- Main-Categories

- Categories

- > Metal Processing

- Milling machines

- Planer-Type Milling M/C - Double Column [1]

- Machining centre

- Machining Center - Vertical [1]

- Makes

- [130]

- AYEL-TECH [1]

- DMG DECKEL-MAHO [1]

- GILDEMEISTER DMG [2]

- YANG EAGLE [2]

- 1 PROFI PRESS [2]

- 100GASPARINI [1]

- 1512 [1]

- 1516 [1]

- 1DURMAZLAR [1]

- 1SCHLEICHER/GSW [1]

- 25 [1]

- 2A620-2 [1]

- 2A622-1 [1]

- 3BERG & SCHMID [1]

- 3HBM [1]

- 3M [1]

- 5VDF BOEHRINGER [1]

- 7POREBA [1]

- A + B [4]

- A+B [9]

- A+B ERBEND [2]

- A+B FASTECH [4]

- A.I. [3]

- AARDING [1]

- AB MARWIN [1]

- ABA [11]

- ABA Z&B [1]

- ABA / ZIERSCH & BALTRUSCH [2]

- ABAWERK [1]

- ABB [1]

- ABENE [1]

- Abfuhrrollenbahn [1]

- ABK [2]

- ABM [1]

- ACCUWAY [1]

- ACETI [1]

- ACIERA [5]

- ACO - Bandschleifer [4]

- ADAM [1]

- ADIGE [1]

- ADIRA [1]

- ADK [2]

- AEG [3]

- AFA [1]

- AFC [1]

- AGEO [2]

- AGIE [8]

- AGIE - CHARMILLES [1]

- AGIE-CHARMILLES [4]

- AH E60 [1]

- Ai [1]

- AJAX [1]

- AK BEND [22]

- AK-BEND [32]

- AKBend [2]

- AKIRA SEIKI [1]

- AKV [1]

- AKYAPAK [13]

- ALBA [1]

- ALIA JUNIOR TAP [1]

- ALIKO [1]

- ALKETT [1]

- ALLIED MACHINE & ENGINEERING [1]

- ALME GERIMA [1]

- ALMI [12]

- ALPA [2]

- ALPEN [1]

- ALPEN SUPER [1]

- ALTEC [1]

- ALVITAR [1]

- ALZMETALL [83]

- AMADA [30]

- AMBOLD [11]

- Amec [2]

- AMF [2]

- AMGA [2]

- AMINO [1]

- AMT [3]

- ANATRONIC [1]

- Anayak [14]

- ANGER [1]

- AP&T [1]

- Apollo [3]

- ARBOGA [3]

- ARCO [1]

- ARGUS - FLOWSERVE [1]

- ARIX [1]

- ARKU [7]

- ARNO [1]

- ARNOLD [1]

- ARNOLD SHINJO [1]

- ARNTZ [4]

- ARO [1]

- AROWA [1]

- ARTHUR KLINK [1]

- Artmann Hamburg [1]

- ASCHERSLEBEN [4]

- ASCHERSLEBEN-SCHIESS [1]

- ASDORF [2]

- ASSERVIMENTI [1]

- ATLANTA [3]

- ATLANTIC [15]

- ATLANTIC / HACO [1]

- ATLAS [1]

- ATORN [2]

- AUDAX [1]

- AUERBACH [5]

- AUERBACH & SCHEIBE [1]

- AUSTEN [1]

- AVIA [8]

- AVIA / MEXPOL [1]

- AVL [2]

- AVM ANGELINI [1]

- AVYAC [4]

- AWEA [4]

- AWEA - CNC [2]

- AWL [1]

- AXA [12]

- AXON LITZ [1]

- AYEL-TECH [2]

- Bach Apolda [1]

- BAD SALZUNGEN [5]

- BAHMÜLLER [2]

- BAIER [2]

- Bakker [3]

- BALCONI [1]

- BALZAT [2]

- BANNING [4]

- Banning Dango & Dango. Andritz [1]

- BARBER COLMAN [1]

- BARON MAX [1]

- Batliboi [2]

- Battenfeld [1]

- BAUBLYS [1]

- BAUER [1]

- BAUHAMMER [1]

- BAYER [1]

- BAYKAL [20]

- BBM [1]

- BBT [1]

- BECHE [2]

- BECHLER [1]

- BECKER & VAN HUELLEN [1]

- Behringer [17]

- BEHRINGER - Halbautomat [1]

- BEHRINGER EISELE [1]

- BEKA-MAK [2]

- BEMA [1]

- BEMATO [4]

- BENDMAK [2]

- BENZINGER [2]

- BERCO [1]

- BERG & SCHMID [83]

- BERG & SCHMID - Halbautomat [1]

- BERG & SCHMID - Vollautomat [1]

- BERG & SCHMID VOLLAUTOMAT [1]

- Berg (ibag) [1]

- BERG SCHMID - Halbautomat [1]

- BERGER [1]

- BERGMANN [1]

- BERGONZI [1]

- BERNADO [1]

- BERNARDO [80]

- BERNSTEIN [1]

- BERRENBERG [4]

- BERTHIEZ [5]

- BETZ [2]

- BEUTLER [8]

- Bewo [8]

- BEYELER [9]

- BEYER [4]

- BGU [2]

- BIANCO [16]

- BIEGEMASTER [23]

- BIGLIA [6]

- BIGSTONE - Vollautomat [1]

- Bihler [2]

- Billaud [1]

- BILZ [1]

- Bimak [2]

- BIMT [1]

- BINNS & BERRY [2]

- BLANCHARD [2]

- BLANSKO [3]

- BLE [1]

- BLEMA-GOTHA [1]

- BLEMAS [1]

- Blies-Bret [1]

- BLOHM [14]

- Blue Laser Tools [1]

- BLUME & REDECKER [1]

- BLUTHARDT [3]

- BMF [1]

- BMSY [3]

- Bode [2]

- BOEHLER [1]

- BOEHRINGER [13]

- Boehringer VDF [1]

- BOELLHOFF [1]

- BOENI [1]

- BOETTCHER & BRUECKMANN [1]

- BOHNER & KOEHLE (BOKOE) [1]

- BOHNER & KÖHLE [4]

- BOHRPOWER [1]

- BOKÖ [1]

- Boldrini [1]

- BOLEY [3]

- BOMAR [4]

- BOMAR - Vollautomat [1]

- BORMASTER [1]

- Bornemann [1]

- BORRIES [1]

- BOSCH [7]

- BOSCHERT [16]

- Bosi Vittorio [1]

- BOTEK [10]

- BRAGONZI [1]

- Brammax [1]

- BREDA [2]

- BRET [1]

- Brevete [1]

- BRIDGEPORT [8]

- Bridgeport ( Bauart ) [1]

- BRIERLEY [1]

- BRINKMANN [1]

- British Federal [1]

- Bronswerk [1]

- BRONX [2]

- Brother [7]

- BRUCKNER [5]

- BRUDERER [9]

- BRYANT [1]

- BRÜCK [1]

- BSM [1]

- BTEV-KLEMOTA [1]

- BTM - VOLLAUTOMAT [1]

- BUCK [1]

- BUDERUS [1]

- Bueltmann [1]

- BULLARD [2]

- BURGER [2]

- BURGHARDT & SCHMIDT [2]

- BURGSMUELLER [2]

- BURKARDT & WEBER [1]

- BURKARDT + WEBER [1]

- BURKHARDT + WEBER [2]

- BURNET [1]

- BUSCH [1]

- BUTLER NEWALL [1]

- BUTLER-ELGAMILL [2]

- BUTLER-NEWALL [4]

- BWF [2]

- BYSTRONIC [16]

- BÖLLHOFF [1]

- C-TEK [3]

- CAMU [2]

- CAMUT [1]

- CANTALUPPI [1]

- CARDINAL [1]

- Carif [1]

- CARL STAHL [1]

- CARMITECH [1]

- CARNAGHI [3]

- CARNAGHI PIETRO [1]

- CARONNO [1]

- CARTACCI [1]

- Castel [4]

- CASTOLIN + EUTECTIC [1]

- CAVENAGHI & RIDOLFI [2]

- Cazeneuve [10]

- CEA [1]

- CEBORA [1]

- Cegielski [2]

- Cerso [1]

- CERUTI [1]

- Cevisa [1]

- CHANNELLETTER [1]

- CHARMILLES [1]

- CHEVALIER [19]

- CHIN FONG [2]

- CHIRON [29]

- CHRISTEN [2]

- CHURCHILL [1]

- CIDAN [3]

- Cinch Mill [1]

- CINCINATTI [1]

- CINCINNATI [11]

- CINCINNATI MILACRON [1]

- CINCINNATI-MILACRON [1]

- CITIZEN [12]

- CLARKSON [2]

- Classica [1]

- CLEARING [1]

- CLOOS [2]

- Cluna [1]

- CMA [2]

- CMC [1]

- CME [4]

- CME SAL [1]

- CMU [1]

- CMZ [8]

- COLCHESTER [21]

- COLGAR [4]

- COLLET [5]

- COLLET & ENGELHARDT [1]

- COLLIN [1]

- Colly [2]

- COLOMBO [2]

- Colortronic [2]

- COMACA [3]

- COMESSA [1]

- COMETA [2]

- COMEV [2]

- COMMERCY [1]

- Comu [1]

- CONCEPT Laser [1]

- CONTUR [6]

- CORDIA [1]

- CORMAK [2]

- CORNAC [1]

- CORNO ITALY [1]

- CORREA [26]

- CORREA/ANAYAK [1]

- CorreAnayak [1]

- COSEN [1]

- COVEMA/SCHWABE [1]

- CRAVEN [1]

- CREUSEN [3]

- CRI-DAN [1]

- CSEPEL [5]

- CUGIR-LORENZ [1]

- Cuoghi [1]

- CUTERAL [1]

- CY257A [1]

- Cyclomatic [1]

- DAEWOO [2]

- DAEWOO DOOSAN [2]

- DAEWOO/DOOSAN [1]

- DAH LIH LIEDER [1]

- DAHLIH [1]

- DAHLIH LIEDER [1]

- DAIKIN [1]

- Daiss + Partner [1]

- DAISS + PARTNER - VOLLAUTOMAT [1]

- DALEX [5]

- DALMASTROJ-Jugoslawien [1]

- DANGO & DIENENTHAL [6]

- DANOBAT [5]

- DANOBAT ESTARTA [1]

- DARLEY [11]

- DAVI [3]

- David [1]

- DDR [4]

- De Moor [1]

- DEBER [1]

- DECKEL [96]

- Deckel Maho [29]

- DECKEL MAHO DMG [10]

- DECKEL- MAHO DMG [1]

- DECKEL-MAHO [31]

- DECKEL-MAHO (DMG) [5]

- DECKEL-MAHO DMG [1]

- DEFUM [4]

- DEGEN [1]

- DEGUSSA-DURFERRIT [1]

- DELAPENA [1]

- Delphin [1]

- DELTA [1]

- DELTAL [1]

- DEMA [1]

- DEMAG [1]

- DENER [2]

- DEPO [2]

- DERATECH [1]

- DESTACO [1]

- DFK [1]

- DIEFFENBACHER [4]

- DIETER HANSEN [1]

- DIGEB [1]

- DIGEP [3]

- DIMECO [8]

- dirinler [2]

- DISA [1]

- DISKUS [5]

- DIVERSE [1]

- DIVERSE ABA BLOHM ELB Z&B [1]

- DIXI [4]

- DMC [1]

- DMF [5]

- DMG [35]

- DMG (5-ACHSEN) [2]

- DMG / MORI SEIKI [1]

- DMG DECKEL MAHO [3]

- DMG DECKEL MAHO GILDEMEISTER [2]

- DMG DECKEL-MAHO [2]

- DMG GILDEMEISTER [5]

- DMG MORI [16]

- DMG MORI SEIKI [3]

- DMG-DECKEL [1]

- DMG-DECKEL-MAHO [2]

- DMG-GILDEMEISTER [3]

- DMG-MORI [1]

- DMG-MORI SEIKI [1]

- DMTG [3]

- Doall [2]

- DOEBELI [1]

- DOERRIES [4]

- DOERRIES-SCHARMANN [1]

- DONAU [2]

- DONAU-KNAPP [2]

- DOOSAN [18]

- DOOSAN DAEWOO [12]

- DOOSAN-PUMA [2]

- DORRIES [1]

- Dr. HOCHSTRATE [2]

- Drabert Sohne [1]

- DREES [2]

- DREHER [12]

- DREISTERN [1]

- DROGEMEYER [2]

- DROOP & REIN [12]

- DUFOUR [1]

- DUGARD [2]

- DUMETA [88]

- DUNKES [28]

- DURMA [63]

- DURMA / METALLKRAFT [3]

- DURMAZLAR [4]

- DÜRING [1]

- DÖRRIES [15]

- DÖRRIES SCHARMANN [2]

- DÖRRIES-SCHARMANN [2]

- EATON [1]

- EBA [1]

- EBU [19]

- ECHEA [3]

- ECKARDT [2]

- ECKERT [1]

- ECKOLD [6]

- ECLAIR [1]

- ECLAIR / PASKOWSKY-Schweiz [1]

- ECLAIRE (SCHWEIZ) [1]

- ED. LUETHY [1]

- EDEL [2]

- EDELHOFF [4]

- EDER [1]

- EHT [42]

- Eichener [1]

- EIGENBAU [3]

- EIGL [1]

- EISELE [11]

- EISELE - Halbautomat [5]

- EITEL [4]

- ELB [20]

- ELB / Hahn & Kolb [1]

- ELB HK Orion [1]

- ELEKTROR [1]

- Elga [1]

- ELHA [2]

- ELMAG [3]

- ELMEA [1]

- ELUMATEC [2]

- ELUMATEC Stabbearbeitung [1]

- EMAG [16]

- EMAG KARSTENS [1]

- EMC [1]

- EMCO [20]

- EMUGE [2]

- ENSHU [1]

- EPPLE [2]

- ERBEND [3]

- Ercole [1]

- ERCOLINA [25]

- ERD [1]

- Erdwich [1]

- ERFI ERGOLINE [1]

- ERFI REKORD [1]

- ERFURT [2]

- Erich Plank / WMW [1]

- ERLO [21]

- ERMAK [63]

- ERNAULT SOMUA [1]

- ERNAULT TOYODA [1]

- ERNAULT-SOMUA [3]

- ERNST [3]

- EROGLU [1]

- ESAB [8]

- Escher [1]

- ESS [1]

- ESSETI (Italien) [1]

- EST-TICINO [3]

- EUMACH [1]

- Euro Mill Maximart [1]

- Euromac [7]

- Europe Shredders [1]

- Eurospark [1]

- EUROTRONIC [1]

- EWAG [2]

- EWS und WNT [1]

- EX-CELL-O [2]

- EXCELLO / Boehringer [1]

- EXNER [13]

- EZset GmbH & Co. KG [2]

- F.I.M. [1]

- Fabr. UNBEKANNT [1]

- Fabr. UNBEKANNT/NOT KNOWN [1]

- Fabris [1]

- Fabris Italy [1]

- Fabrius [1]

- FACCIN [5]

- FADAL [4]

- FAESSLER [1]

- Fag [1]

- Fahr, Epping etc [1]

- FALCON [1]

- FALKEN [27]

- FAMAR [2]

- Famas [1]

- FAMUP [4]

- FAN [1]

- FANUC [8]

- FANUC ROBODRILL [1]

- FANUC-STAMA [3]

- FARINA [11]

- Farman [1]

- FARREL [1]

- FASTECH [3]

- Fastenrath [1]

- FASTI [56]

- FAT [3]

- FAVRETTO [4]

- FDB [1]

- FDF [1]

- FDF Fritz Duesseldorf Freiburg [1]

- FECKER [1]

- FEELER [4]

- FEHLMANN [11]

- Fein [3]

- FEINMECHANIK DECKEL [1]

- FEINMECHANIK MICHAEL DECKEL [1]

- FEINMESSZEUGFABRIK SUHL [1]

- FEINTOOL [2]

- FEINTOOL-OSTERWALDE [1]

- FELSOMAT [1]

- Femco [1]

- FEMCO-ASTRHAL [1]

- FEMCO1200 [1]

- FEMI [3]

- FERINA [1]

- FERMAT [1]

- FERREL [1]

- FESTO [6]

- FETTE [14]

- FETTE - PWS - KLINGELNBERG [1]

- FEXAC [1]

- FEZER [1]

- FIDIA [1]

- FIL [2]

- FILTOO [1]

- FIM / AMADA [1]

- FIM / INDUMASCH [1]

- FIM/Indumasch [1]

- FIMI [2]

- FINKEN [4]

- FINN POWER [1]

- FINTEK [18]

- FIRST [3]

- FISCHER [8]

- FKD-FEICHTER [1]

- FLAMEFAST [1]

- FLOTT [23]

- Flutec [1]

- FMB [1]

- FMS [3]

- Folmer [1]

- FOM [2]

- FOM Industrie [1]

- FOOKE [1]

- FOREST LINE [1]

- FOREST-LINE [2]

- Forges de Gilly [2]

- FORKARDT [2]

- FORMAT [3]

- FORTE [6]

- FORTEMAT [1]

- Fortuna [2]

- FPT [6]

- FRAMAG [1]

- Frech [1]

- FREI [4]

- FREMTAS [1]

- Frenco [1]

- Fritsch [1]

- FRITZ HECKERT [1]

- FRITZ MUELLER [1]

- FRITZ WERNER [4]

- FROEMAG [1]

- FROMMIA [1]

- FRORIEP [13]

- FRORIEP-SCHIESS [1]

- FRÖMAG [8]

- Fukuno Seiki [2]

- FURRER MUELLER [1]

- FÄSSLER [1]

- G + K [1]

- G.O.S. [1]

- GABRO [1]

- Gaco [1]

- GALDABINI [1]

- Gambin [1]

- GARANT [1]

- GASPARINI [8]

- GAUTHIER [1]

- Gebr. BAYER [1]

- GEBR. HAU [1]

- GECAM [2]

- GEFI GYOER [1]

- GEHRING [9]

- GEIBEL & HOTZ [6]

- GEIBEL + HOTZ [1]

- GEIBEL&HOTZ [1]

- GEKA [41]

- Gelber Bieger [1]

- GEMA [1]

- GEMINIS [9]

- GEORG [1]

- GEORG FISCHER [4]

- GEORG MÜLLER [1]

- George [7]

- George Fischer [1]

- GER [3]

- GER, Spanien Lizenz ELB [1]

- GERD WOLFF [4]

- Gerver [2]

- Geuma [2]

- GEWEFA [1]

- GHIRINGHELLI [1]

- GIANA [1]

- GIDDINGS & LEWIS [2]

- GILDEMEISTER [58]

- GILDEMEISTER & KNOLL [2]

- GILDEMEISTER (teilueberholt) [2]

- GILDEMEISTER- DMG [1]

- GILDEMEISTER/gratziano [1]

- GILLARDON [8]

- GISAG [1]

- GLASMACHER [1]

- GLAUCHAU [2]

- GLEASON [9]

- GLEASON HURTH [4]

- GLEASON PFAUTER [1]

- GLEASON- PFAUTER [9]

- GLEASON-PFAUTER [4]

- GLEASON-PHOENIX [1]

- GMG [1]

- GMN [2]

- GMN Georg Müller [1]

- GMN Georg Müller Nürnberg [1]

- GOEBEL/MSO [1]

- GOOD AIRE [1]

- GOODWAY [5]

- Goodway GS 2800 M [1]

- GORNATI LEGOOR [1]

- Gorter [3]

- Gosmeta [1]

- Goyar [1]

- Gozua [1]

- GRAEBENER [3]

- GRAEBENER multi-station press [1]

- GRAUL [1]

- GRAULE [3]

- GRAVER GRINDER [1]

- GRAZIANO [1]

- GREENLEE [1]

- GREIF [7]

- GRIT [3]

- GROB [10]

- GROETZINGER [1]

- Gromatic [1]

- GRÄBENER [6]

- GRÖTZINGER [1]

- GSP [3]

- GSW [2]

- GSW SCHWABE [10]

- GSW-SCHWABE [2]

- GUALDONI [2]

- GUIFIL [2]

- Guitti [1]

- Gurutzpe [3]

- GWF [1]

- GWF-MENGELE [1]

- GWS [1]

- GÜHRING [36]

- GÜHRING / TITEX [1]

- GÖCKEL [2]

- H & H [1]

- HAANE [1]

- HAAS [19]

- HABOR [1]

- HACO [16]

- HAEMMERLE-GF BRUGG [1]

- Haeusler [7]

- HAFFNER - Kopierfräse [1]

- HAGEN & GOEBEL [4]

- Haginger [2]

- HAHN & KOLB [6]

- Hahn&Kolb [1]

- HAHNDORF [1]

- HAHNDORF (RUWO) [1]

- HAHNDORF - RUWO [1]

- HAINAN GREAT [1]

- HAMM [1]

- HANAU [1]

- HANDTMANN [2]

- HANG [1]

- HANKOOK [4]

- HANNIFIN [1]

- HANS LINDNER [1]

- HANS SCHOEN [2]

- Hapremec [1]

- HARDINGE [13]

- HARDINGE-BRIDGEPORT [1]

- HARRISON [4]

- HARTFORD [12]

- HASENCLEVER [1]

- HATASTAR [1]

- HATEBUR [2]

- HAULICK [4]

- HAULICK & ROOS [5]

- HAULICK + ROOS [1]

- HAULICK+ROOS [1]

- HAUNI-BLOHM [1]

- Haunstrup [1]

- HAUSER [18]

- HAUSER-SIP [1]

- HAUSLER [1]

- HBM [61]

- HEAD [1]

- Heckert [9]

- HECKERT-STARRAG [2]

- Heckler & Koch [1]

- HECKLER & KOCH [1]

- HEDELIUS [9]

- HEDELIUS - Vertikal [3]

- HEGENSCHEIDT [3]

- HEGNER [1]

- HEIDENHAIN [23]

- HEIDENREICH & HARBECK [7]

- HEIDENREICH & HARBECK [1]

- HEILBRONN [11]

- HEINRICH [1]

- Heinrichsgluck [1]

- HEINRICHSGLUECK [1]

- HEINRICHSGLÜCK [1]

- HEKUS [1]

- HEL - WITA [1]

- HELI COIL [4]

- HELIOS [1]

- HELLER [9]

- HELMERDING [12]

- HEMBRUG [2]

- HENNINGER [1]

- HENSEL [13]

- HENSOLDT WETZLAR [1]

- HERA [11]

- HERAEUS [1]

- HERAEUS-VOeTSCH [1]

- HERBORN [2]

- HERKULES [5]

- HERMES [6]

- HERMLE [47]

- HERMLE (5-Achsen) [1]

- HERRMANN [2]

- HERTEL [2]

- HESKA [6]

- HESSAPP [4]

- HESSE [8]

- HESSE by BEKA-MAK [28]

- HESSE by COILTECH [4]

- HESSE by DIRINLER [13]

- HESSE by DURMA [69]

- HESSE by FRESAN [5]

- HESSE by ISITAN [23]

- HESSE by JHL [3]

- HESSE by LFSS [35]

- HESSE by SAHINLER [23]

- HETO [1]

- HETTNER [1]

- HEUEN - CLOOS [1]

- HEUSER [2]

- HEWA [1]

- Heyligenstaedt [17]

- HEZEL [3]

- HEZINGER [2]

- HIDROLIKSAN [19]

- HILGELAND [1]

- Hilgers [1]

- HILLE [2]

- HILLER [1]

- HISWeld [7]

- HITACHI [1]

- HITACHI SEIKI [1]

- HITACHI SEIKO [1]

- HITACHI-SEIKI [1]

- HIW HELMERDING [1]

- HK CON [1]

- HKS [1]

- HM [10]

- HM MACHINERY [4]

- HM MACHINERY Tischbohrmaschine [1]

- HMB [1]

- HMTCL [1]

- HNK MACHINE TOOL CO [3]

- Hobart [1]

- HOCHSTEIN [4]

- HOEFLER [7]

- HOFFMANN [3]

- HOFMANN [1]

- HOL-MONTA [1]

- HOLKE [1]

- Hollandprofiel [1]

- HOMA / Gebr. Hoffmann [1]

- HOMMEL HERCULES [1]

- HOMMELWERKE [1]

- HP [1]

- HPG [1]

- HPM [1]

- HS-AUTOMATION [3]

- HSP [1]

- HUBER [1]

- Hueller [1]

- Hunger [2]

- HURCO [25]

- HURON [16]

- HURTH [14]

- HURTH-MODUL [2]

- HUVEMA [71]

- HUVEMA - Halbautomat [1]

- HWACHEON [5]

- HYDAC [1]

- HYDRAP [14]

- Hydro Meca [1]

- HYLATECHNIK [3]

- HÜLLER HILLE [2]

- HÜLLER – HILLE (MAG) [1]

- HÜLLER-HILLE [3]

- Hyllus [1]

- HYMAG [1]

- HYUNDAI [7]

- HYUNDAI KIA [2]

- HYUNDAI WIA [2]

- HYUNDAI-KIA [1]

- HÄMMERLE [2]

- HÄMMERLE - GF BRUGG [2]

- HÄUSLER [3]

- Häwa [1]

- HÖFLER [3]

- i-tools [2]

- IBARMIA [7]

- IBERDRILL [10]

- IBERIMEX [3]

- IBERIMEX MVR (teilueberholt) [1]

- ICKING [1]

- IFANGER [2]

- Ihermal Arc [1]

- Imada [1]

- IMATEC [3]

- IMCAR [3]

- Imec [1]

- IMES-ICORE [1]

- IMET [3]

- IMS [2]

- IMTI [2]

- INA [2]

- INDEX [45]

- INDUMA [1]

- INDUMASCH [9]

- INDUMASCH SIEGEN [1]

- Industriefilter-Service GmbH S [1]

- INFRATIREA [3]

- INGERSOLL [210]

- INGERSOLL-BOHLE [5]

- INNOTOOL [3]

- INNSE [1]

- INOX [1]

- INTEMACH [4]

- INTERTEST [1]

- INTOS [2]

- INVEMA [1]

- Irle [3]

- IRON / RDI Group [1]

- ISAM [1]

- ISCAR [2]

- ISELI [1]

- Isitan [1]

- ISOMA [1]

- ITALMACH [1]

- ITB [1]

- IWK [2]

- IWK PEKRON [4]

- IWK Pressen [1]

- IXION [14]

- IXION AUERBACH [1]

- J&W [2]

- J. Behr [1]

- JACOBSEN [3]

- JAECKEL [1]

- Jaeckle [2]

- JAESPA [5]

- JAESPA - Vollautomat [1]

- Jafo [1]

- JAKOBSEN [4]

- James Ruben [1]

- JANTSCH [1]

- JAVAC [3]

- JELSINGRAD [2]

- JENNY [2]

- Jesco [1]

- JESPA [1]

- JESSERNIGG & URBAN [1]

- JESSEY [2]

- Jessey Champion [1]

- Jinn Fa [1]

- JMC [1]

- JMTCL [3]

- JOBS [1]

- JOERG [3]

- JOHNFORD [4]

- JOISTEN & KETTENBAUM [1]

- JOISTEN & KETTENBAUM [2]

- JONES & SHIPMAN [1]

- JONES SHIPMAN [1]

- JONESCHEIT [1]

- JOOS [1]

- JOPP [1]

- Jorg [14]

- JORNS (Verkauft) [1]

- JOTES [2]

- Jrle [1]

- JT [1]

- JUARISTI [11]

- JuaristiZ/W [1]

- Jugenthal [1]

- JULIUS [1]

- JUNG [17]

- JUNGENTHAL [7]

- JUNKER [7]

- JUTGER [1]

- JWelding [13]

- KADIA [3]

- Kaempf [1]

- KAFO [2]

- KAI TEC [1]

- KAISER [22]

- KALTENABCH [1]

- KALTENBACH [24]

- KAMI [33]

- Kao Ming [5]

- KAPEMA [7]

- KAPP [7]

- KARATS [3]

- Karmak [1]

- Karmetal [3]

- KARSTENS [10]

- KARSTENS / WEISS [1]

- KART [1]

- KASTO [35]

- KASTO - AUTOMAT [1]

- KASTO - Halbautomat [2]

- KASTO - Vollautomat [2]

- KASTO -Vollautomat [2]

- KEBE [1]

- KEF [1]

- KEHREN [1]

- KEILPART [1]

- KEKEISEN [4]

- KELCH [4]

- KELLENBERGER [31]

- KELLENBERGER UEBERHOLUNG [1]

- KELLER [1]

- Kemmerich [7]

- KEMPER [2]

- Kemppi [2]

- KEMT [1]

- Kennametal [4]

- KENT- HEAD [1]

- KEPROMA AG [1]

- KERN [5]

- KERN-DMT [1]

- KESSLER [1]

- Keuro [1]

- KIA [1]

- KIESERLING [1]

- Kiheung [9]

- Kikinda [2]

- KINEX [1]

- KINGSLAND [4]

- KIRA [1]

- KIRSCHBAUM [1]

- KISTLER [2]

- KITAMURA [6]

- KIWA [2]

- KIWA EXEL CENTER [1]

- KJELLBERG [1]

- KLAASSEN [1]

- Klaeger [2]

- KLAIBER [1]

- KLEIN [1]

- KLINGEL [3]

- KLINGELNBERG [24]

- KLINGELNBERG-OERLIKON [2]

- KLINGSPOR [1]

- KLOPFER [2]

- KLOPP [6]

- KLOPP-KORRADI [2]

- KLÄGER [1]

- KNAPP [1]

- KNAPP-DONAU [1]

- Knoll [1]

- KNUTH [14]

- KNUTH / DURMA [2]

- KOBA [1]

- KOCH [1]

- Koebau Multimat [1]

- Koelsch-Foelzer-Werke [1]

- KOENIG & BAUER [2]

- KOEPFER [3]

- KOHCHIYAMA TECH [2]

- KOHLER [10]

- KOHLER / WEINGARTEN [1]

- KOHLER 6 HI [1]

- Koike [2]

- KOLARC [1]

- KOLB [12]

- KOLB-SCHMALTZ [1]

- Kolle [1]

- KOLOMNA [2]

- Kolster [1]

- KOMATSU [1]

- Komplette Haerterei [1]

- KONDIA [7]

- KONHIDROLIKSAN [1]

- KONRAD SEIDLER [1]

- KORRADI [2]

- KOVOSIT MAS [1]

- KOVOSVIT [1]

- Kownatzki-Reishauer [2]

- KRAEMER [2]

- KRAFT [135]

- KRAFT (Etech) [1]

- KRAFT (JAP) [3]

- KRAFT (Robbi) [2]

- KRAFT (Sieg) [1]

- KRAFT (SMTCL) [1]

- KRAFT (Tongtai) [2]

- KRAFT (YSP) [2]

- Kraft/Praise [3]

- KRAFT/Skymaster [3]

- KRAMATORSK [1]

- KRAMER [3]

- KRAUSE [1]

- Krauseco-Mauser [2]

- KROLLMANN [7]

- KRUPP [2]

- KRUPS [1]

- KRYLE [1]

- KUGEL MUELLER [2]

- KUHLMANN [1]

- KUKA [1]

- KUNMING [1]

- KUNZMANN [9]

- Kusters [1]

- KÖLLE [4]

- L-TEC [1]

- LA RIGIDE [1]

- LACFER [3]

- Laeis [1]

- LAEPPLE [9]

- LAG [1]

- LAGUN [8]

- LAGUN FBF 1200 [1]

- LAMBERT - JOUTY [1]

- LANG [1]

- LANGZAUNER [1]

- LASCO [1]

- Lastek [1]

- LAUFFER [11]

- LE [1]

- LE 250 C [1]

- LEADWELL [14]

- Lefort [1]

- LEINEN [2]

- LEINHAAS [2]

- LEISTRITZ [2]

- LEITZ - HEXAGON [2]

- LENZEN [4]

- LGB [4]

- LGB HURON [1]

- LIDKOEPING [2]

- LIEBER [1]

- LIEBERGELD multi-station press [1]

- LIEBHERR [13]

- LIECHTI [1]

- LIMONTA / EUROSLITTER [1]

- Lincoln [1]

- Lincoln Electric [1]

- LINDE [1]

- LINDNER [4]

- LINEAR ABRASIVE [1]

- Lingk und Sturzebecher [1]

- LIPTOVSKE STROJARNE [1]

- LISSE [1]

- Lissmac [3]

- Lista [2]

- LITZ [1]

- LIV [1]

- Livet [1]

- LNS [1]

- LOCH [1]

- LOCKFORMER [3]

- LODI [1]

- LODIFLEX CASER [1]

- LOESER [1]

- LOIRSAFE [1]

- LOMBARDO [1]

- LORCH [2]

- LORENZ [18]

- LOROCH [1]

- LOTZE [8]

- Lowener [1]

- LUBRO Grisetti [1]

- LUIGART [3]

- LUNAN [1]

- Luxmill [1]

- LVD [36]

- LÄPPLE [1]

- LÖW [1]

- M+A [6]

- MA.TE [7]

- MAAG [7]

- MABU [1]

- MACMOM / INAS [1]

- MACMON [5]

- MAE [8]

- MAEGERLE [1]

- MAG [1]

- MAGDEBURGER [2]

- MAHLE [1]

- MAHO [42]

- MAHO-GRAZIANO [1]

- MAHO-HANSEN [1]

- MAHR [10]

- MAIER [3]

- MAILLEFER [1]

- MAJEVICA [1]

- MAKINO [17]

- MAN [1]

- Mandelli [1]

- MANURHIN [1]

- MANURHIN MENTI [1]

- MANZONI [1]

- MAP [1]

- MARIO CARNAGHI [1]

- MARTIN [3]

- Mas [13]

- Masch [2]

- MASTER HEAD SHOP [1]

- MATCHMAKER [2]

- MATEC [10]

- MATHEYS [1]

- MATRA [6]

- MATRA JOHNFORD [2]

- Matricola [1]

- MATSUURA [9]

- MATTISON [1]

- MAUSER [2]

- MAX MUELLER [2]

- MAX MUELLER-GILDEMEISTER [1]

- MAX MÜLLER [1]

- Maximart [2]

- Maximum [1]

- MAXION [11]

- MAY [2]

- MAYSS [1]

- MAZAK [76]

- MAZAK - CNC [4]

- MB [5]

- MBH [1]

- MCM [3]

- MDW [1]

- MEB [1]

- MEBA [13]

- MEBA - VOLLAUTOMAT [6]

- MECOF [2]

- MEGEY [3]

- MEIER WERKE [1]

- MELCHIORRE [2]

- Memoli [1]

- MENGELE [12]

- MEP [78]

- MEP - Halbautomat [14]

- MEP - VOLLAUTOMAT [10]

- MERKLE [3]

- MERLI CLOVIS [3]

- MERLIN [1]

- MESSER [3]

- Messer Griesheim [4]

- MESSER GRIESHEIM / POLLRICH [1]

- Messgeraet Schatz GmbH [1]

- MESSMA-KELCH [2]

- METABO [5]

- Metal WAG [1]

- Metallit [3]

- METALLKRAFT [15]

- Metalwerk [1]

- METAS [1]

- METBA [2]

- METORA [4]

- Metron [1]

- MEULEMAN [1]

- MEUSER [8]

- MEWAG [1]

- MEWAG IXION [1]

- MEXPOL [2]

- MEYER-SCHNEGG [1]

- MFD [1]

- MFD - HOESCH [4]

- MG [4]

- MIB [4]

- MICHAEL DECKEL [1]

- MICROCUT [4]

- MICROMILL [2]

- MICRON [1]

- MICROSTEP [1]

- MICROTURN [2]

- Midsaw [1]

- MIGATRONIC [3]

- MIGTRONIC Schweißgerät DIALO [1]

- MIKROCUT [1]

- MIKROMAT [4]

- MIKRON [48]

- MIKRON - HAAS [2]

- MIKRON AGIE CHARMILLES [2]

- MIKRON HAAS [1]

- MIKRON-AGIE CHARMILLES [3]

- Milko [1]

- Miller [2]

- MILLUTENSIL [2]

- MILUTENSIL [1]

- MININI [4]

- MINO / SAMO [1]

- MINUTE MAN [1]

- Mios [2]

- MIRAFU [1]

- MISAL [1]

- MITSUBISHI [3]

- MITSUI SEIKI [2]

- MITUTOYO [10]

- MITUTOYO KA-Counter [1]

- MIYANO [3]

- Mk Technology [1]

- MODUL [1]

- MOESSNER [1]

- MOeSSNER REKORD [1]

- MONDIALE [11]

- MONFORTS [18]

- MONNIER & ZAHNER [2]

- Monnier + Zahner [1]

- Monofap [1]

- MOORE [3]

- MORANDO [2]

- MORARA [2]

- MORI SEIKI [62]

- MORI-SEIKI [1]

- MOSER [1]

- MOTOM [1]

- MOTOMAN [2]

- MPK [6]

- MRF [1]

- MSO [2]

- MT CUT [1]

- MTA [1]

- MTcut [1]

- MTE [2]

- MTM [1]

- MTorres [1]

- MUBEA [15]

- MUEGA [1]

- MUELLER [24]

- MUeLLER OPLADEN [1]

- MUELLER PAUL [1]

- MUELLER-GEFREES [1]

- MUELLER-WEINGARTEN [2]

- MUHR & BENDER [7]

- Muller [1]

- MULTIFIX [73]

- MULTIFIX C [1]

- MULTIFORM [1]

- Multimig [1]

- MUM [1]

- Munk [1]

- MUNTHE-MONOPOL [1]

- MURATEC [6]

- MVD [1]

- MVE BAUART VDF [1]

- MYANO [2]

- Myford [1]

- müga [1]

- MÜGA (teilueberholt) [1]

- MÜLLER [32]

- MÜLLER - WEINGARTEN [2]

- MÜLLER INNSBRUCK [1]

- MÜLLER WEINGARTEN [2]

- MÜLLER-WEINGARTEN [3]

- MÄGERLE [1]

- MÖSSNER [5]

- MÖSSNER REKORD [1]

- N/A [1]

- NAGEL [5]

- NAKAMURA [8]

- NAKAMURA TOME [4]

- NAMSUN [1]

- NARDINI [2]

- NARVIK [6]

- Naxos [1]

- Naxos Union [5]

- NAXOS-UNION [3]

- NAXOS-UNION EMAG [1]

- Nederman [1]

- NEEF [1]

- NEFF [8]

- NELSON [3]

- NEU [1]

- NEXTURN [1]

- nicht ersichtlich [1]

- NICOLAS CORREA [2]

- Nieland [1]

- NIIGATA [3]

- NILES [11]

- NILES-SIMMONS [1]

- NIMAK [6]

- Nippon [1]

- NISSHINBO [1]

- NKO [5]

- NN [60]

- NOBLE & LUND [1]

- NOMOCO [2]

- NONAME [2]

- NORMATIC [1]

- NORTE [3]

- NOSOTTI [1]

- NOSSTEC ( LUNA ) [3]

- NRA [1]

- NYDALS [1]

- OBRU [3]

- OERLIKON [10]

- OERLIKON-BOEHRINGER [2]

- OERLIKON-KLINGELNBERG [1]

- OEVERMANN [1]

- OEVERMANN & NIEDRINGHAUS [1]

- OHLER [1]

- Okamoto [3]

- OKK [4]

- OKUMA [26]

- OLAER [1]

- OMAG [2]

- OMCN [6]

- OMCN / BAHCO [1]

- OMERA [1]

- OMES [1]

- OMG [1]

- ONA-DATIC [1]

- ONSAL [1]

- OOYA [1]

- OPTIdrill [2]

- OPTIdrill Tischbohrmaschine [2]

- OPTIMUM [14]

- OPTREL [2]

- OSTAS [23]

- OTC [1]

- OTTO MÜLLER [1]

- Overige machines/toebehoren [1]

- OZMACHINE [2]

- P/A [1]

- PADOVANI [2]

- Pallmann [1]

- PAMA [6]

- PANTHER [1]

- PARPAS [2]

- PARX [1]

- PASQUINO [2]

- PAV [1]

- PAVENTA [1]

- PBR [2]

- PEDDINGHAUS [30]

- PEE WEE [1]

- PEE-WEE [9]

- Pegard [6]

- PEGAS - VOLLAUTOMAT [1]

- PEGASUS [1]

- PEHAKA [3]

- PEI [1]

- PEISLER [1]

- PEL [1]

- PELI [1]

- PELISSIER [1]

- PENSOTTI [1]

- PERFECT [1]

- PERSICO [1]

- PETEWE [1]

- PFAUTER [15]

- PFAUTER/RICHARDON [1]

- PFEIFER [1]

- PFEIFFER [1]

- Pferd [2]

- Phoenix [3]

- PIESOK [2]

- PIETRO CARNAGHI [2]

- Pietrocarnaghi [1]

- PINACHO [12]

- PITTLER [4]

- PLACKE [5]

- PLANK / WMW Heckert/Saalfeld [1]

- PlasmaCut [3]

- PME [4]

- Polymat [1]

- PONAR, POLEN [1]

- PONTIGGIA [2]

- POREBA [20]

- POSALUX [2]

- POSMILL [1]

- Post [1]

- Powertherm [1]

- PRB [1]

- PREISSER [2]

- PresseRoss [1]

- PRESSTA-EISELE [1]

- PRIMA INDUSTRIE [1]

- Primat [1]

- PRIMINER [1]

- Prinzing [2]

- Profi Press [2]

- PROFIPRESS [8]

- PROFIROLL [1]

- PROFIROLL BAD DUEBEN [1]

- PROMECAM [2]

- PROMOTECH [1]

- PROTAC ZAAR [2]

- PROTH [3]

- PRVOMAJSKA [1]

- PRÄWEMA [1]

- PSM [2]

- PULLMAX [4]

- PUMA [1]

- PUSKAS SIERRA [1]

- PWK [2]

- PWS [23]

- PWZ [1]

- QIQIHAR [1]

- QUANTUM [2]

- Quaser [8]

- QUASER (5-ACHSEN) [2]

- QUICK TECH [1]

- R+S Technik [1]

- RABBA [10]

- RABOMA [4]

- RADLER & RUF [1]

- RAFAMET [6]

- RAGNAR [6]

- RAMBAUDI [2]

- Rambo [1]

- RAMO [1]

- Rapid [3]

- RAPIDE [3]

- RAS [29]

- RASKIN [1]

- Raskin Suisse [1]

- RASOMA [1]

- RASTER [5]

- RASTER ZEULENRODA [1]

- RAUSCH-GRATOMAT [1]

- RAVENSBURG [13]

- Ravensburg P 30 [1]

- RAZIOL [1]

- RDB [3]

- RDB / PELMA [1]

- RECKERMANN [12]

- REFORM [6]

- REHM [3]

- REICH [1]

- REICHENBACHER [1]

- REICHLE & KNÖDLER [1]

- REIDEN [11]

- REINECKER [1]

- REINECKER KOPP [1]

- REINHARDT [1]

- REIS [22]

- REISHAUER [15]

- REITER [1]

- REKORD [1]

- REM [3]

- REMA [8]

- REMS [1]

- RENISHAW [3]

- REXON [1]

- REXROTH [2]

- RFR [1]

- RGA [1]

- RHODES [1]

- RHTC [7]

- RHTC - Portalpresse [1]

- RIBON [1]

- Richter [1]

- RICHTER [2]

- RICHTER-IWK [1]

- RICHTWERK [2]

- RICHYOUNG [1]

- RIDGID [1]

- RIDGID Kollmann [1]

- RIELLO [1]

- RIETSCHLE [1]

- RITTAL [1]

- RIVELICA [1]

- RIVETT [1]

- Robbi [4]

- ROEHM [3]

- ROEMHELD [1]

- Roescher [1]

- ROEWAG [1]

- ROFIN [1]

- Rohbi [1]

- ROHDE & DÖRRENBERG [1]

- ROLLERS [1]

- ROLLMAK [6]

- ROLLOMATIC [1]

- ROLLWALZTECHNIK [1]

- ROMI [2]

- ROSA [3]

- ROSA ERMANDO [1]

- ROSENDAHL [1]

- ROSI [1]

- Rothenberger [2]

- Roundo [7]

- Rowac [3]

- RSA [2]

- RTK [1]

- RUCOCO [1]

- RUEBENACH [1]

- RUESCH [1]

- Ruhrmann [1]

- RUNDTISCH [1]

- RURACK [5]

- RÖCHER [1]

- RÖDERS (HSC) [1]

- RÖHM [8]

- RÖHM (wahrscheinlich) [1]

- RÖSLER [1]

- S/P [1]

- Saacke [5]

- Sacem [1]

- SACHMAN [2]

- SACK & KIESSELBACH [2]

- Saeilo [5]

- SAF [6]

- SAFAN [11]

- SAFOP [1]

- SAFOP LEONARD [2]

- SAGITA-BEYELER [1]

- SAHINLER [8]

- SAIMP [1]

- SALTEC [1]

- SALVAGNINI [1]

- SAMAG [1]

- SAMPUTENSILI [1]

- Samsung Smec [1]

- SAMU [1]

- SAMUR [1]

- SANDERS [6]

- Sandingmaster [1]

- SANDT [2]

- SANDVIK [50]

- SANGIACOMO [1]

- SARO [2]

- SARTORIUS [2]

- SARTORIUS Ultra-Cleaner [1]

- SATO [1]

- SATRONIK [1]

- SAUTER [1]

- SAW KING [1]

- SAY-MAK [2]

- SBC [3]

- SBN [3]

- SBN Tischbohrmaschine [1]

- SCANSONIC [1]

- SCANTOOL [6]

- SCHAAL [1]

- SCHAEFER [3]

- SCHAERER [4]

- SCHAFFNER [2]

- SCHANBACHER [5]

- SCHARF WESTFALIA [1]

- Scharmann [22]

- SCHARRINGHAUSEN [3]

- SCHAUBLIN [9]

- SCHAUDT [9]

- SCHECHTL [8]

- SCHERER FEINBAU [3]

- SCHIES5 [1]

- SCHIESS [12]

- SCHIESS Froriep [1]

- SCHIESS- FRORIEP [4]

- SCHIESS-FRORIEP [9]

- SCHIESS-KOPP [1]

- SCHIESS-NASSOVIA [1]

- Schirmer Plate Simpelkamp SPS [1]

- SCHLATTER [1]

- SCHLEICHER [12]

- Schleicher Ideal Edelhoff [1]

- SCHLEIFPOWER [2]

- SCHLEIFSPINDEL [1]

- SCHLICK [2]

- SCHMALTZ [2]

- SCHMALZ [1]

- SCHMIDT [2]

- SCHMIDT Tempo [1]

- SCHMIDT-TEMPO [1]

- SCHNEIDER [1]

- SCHNUTZ [2]

- SCHOEN [14]

- SCHOLLE [2]

- SCHRAMM & LICHNER [1]

- SCHROEDER [10]

- SCHRÖDER [6]

- SCHRÖDER FASTI [1]

- SCHUBERT [2]

- SCHUECO [1]

- SCHULER [31]

- SCHULER HYDRAP [1]

- SCHULER SMG [1]

- SCHULER-HYDRAP [1]

- SCHULER-WEINGARTEN [1]

- SCHUMACHER, System TRENNJÄGER [1]

- SCHUMAG [1]

- Schwartze-Wirtz [1]

- SCHWARZ [2]

- SCHWARZE-WIRTZ [4]

- SCHWEGLER [1]

- Schweisskraft [3]

- SCHWERDTFEGER [1]

- SCHÜTTE [9]

- SCHÄFER [9]

- Scotchman [1]

- SCRIPTA [1]

- SCS [1]

- SCULFORT [1]

- SECO [35]

- SECODEX [3]

- SEDIN [4]

- SEI Laser [1]

- SEIGER [7]

- SELECT [1]

- SEMA BRIO [1]

- SERTOM [1]

- SEVERT [4]

- SGP [1]

- Shadomaster [1]

- Shigiya [1]

- Shop Press [1]

- SHORE [1]

- SHW [7]

- SIA [1]

- Sicap [1]

- Sices [2]

- SICMI [61]

- SIDEROS [7]

- Siduza [1]

- SIEGMUND [65]

- SIEGMUND - ZUBEHOER [8]

- SIELEMANN [3]

- SIEMENS [1]

- SIEMPELKAMP [1]

- SIG [1]

- SIGMA [1]

- SILISTRA [2]

- SILIT [1]

- SIMASV [2]

- SIMAT [2]

- SIMEK [1]

- SIMON [3]

- SIMPAC [1]

- SIMPLON [1]

- Sintris [1]

- SIP [10]

- SIP - Hauser [1]

- Sip Hauser [1]

- SIT [3]

- SIXIS [1]

- SKET [1]

- SKF [2]

- SKODA [20]

- Sky Master - KRAFT [1]

- SLM [1]

- SMC [2]

- SMEC [1]

- SMERAL [2]

- SMG [14]

- Smitweld [2]

- SMM [1]

- SMS EUMUCO-MEER [1]

- SMT [2]

- SMT - PULLMAX [2]

- SMT Pullmax [1]

- SMTCL [1]

- SNK-SHIN NIPPON KOKI [1]

- SOLID [7]

- SOMAB [5]

- SOMET [1]

- SOMUA CNC [1]

- SOPREM [3]

- SORALUCE [20]

- SOYER [2]

- SPANNFIX [1]

- SPANNTOP [1]

- Speedomatic [1]

- SPERONI [1]

- SPINNER [18]

- SPIRAL [2]

- SPOERRI [1]

- SPV [1]

- Stahlgruppe [1]

- STAHLSEIL [1]

- STAMA [10]

- STAMA ROBODRILL [2]

- STANEXIM [2]

- Stanko [1]

- Stanko [22]

- STANKO SEDIN [1]

- STAR [9]

- Staral [1]

- STARRAG [2]

- STARRAG HECKERT [2]

- STARRAG-HECKERT [3]

- STARTRITE [3]

- Starvision [1]

- STEFOR [1]

- STEINEL [3]

- STEINER [3]

- Stenhoj [1]

- STENHOJ [2]

- STEPHAN [1]

- STIERLI - BIEGER [2]

- STIHL [1]

- Stimin / Volz [1]

- Storebro [1]

- STRAMA [1]

- Strands [1]

- Strausak [1]

- STRECKER [2]

- Strekwals [1]

- STROHM [3]

- STROJAREN PIESOK [1]

- STROJARNE [1]

- STROJTOS [1]

- Stroter [1]

- STUCKMANN & HILLEN [1]

- STUDER [12]

- STUDER NR. 325 [1]

- STUeCKMANN & HILLEN [1]

- STUERMER [1]

- STUHLMANN [2]

- Stumpf [1]

- STÜCKMANN + HILLEN [2]

- Style [1]

- STÖCKEL [1]

- STÖLTING [1]

- SUHL [1]

- SUHNER [1]

- SUMITOMO-SHIBAURA [2]

- SUNDSTRAND [1]

- SUNNEN [8]

- SUPERMAX [2]

- SUPFINA [2]

- SW [2]

- SW SCHWÄBISCHE WERKZEUGMASCHIN [2]

- SW-SCHWäBISCHE WERKZEUGMASCH. [2]

- SÜDMETALL [1]

- SYIL [1]

- SYKES [1]

- SZIM [1]

- TACCHELLA [2]

- TACCHI [6]

- Tadu [4]

- Tai Piin [1]

- TAILIFT [6]

- Takang [1]

- TAKISAWA [6]

- TAM [1]

- Tauring [2]

- TBT [4]

- TEAP [1]

- TECHNICA [4]

- TECHNICA (SCHWEIZ) [1]

- TECHNIKA [1]

- TECNA [3]

- TEHAG [3]

- TEKA [2]

- Tekna [1]

- TELWIN [1]

- TESA [4]

- TF GmbH [1]

- THEIS [1]

- THERMAL ARC [1]

- THERMAL ARC [1]

- THIEL [4]

- THIELENHAUS [3]

- THIELER [1]

- Thijssen [1]

- TIBO [2]

- TILGERT [2]

- Timesavers [3]

- TITAN [1]

- TITAN (PAMA) [2]

- TITAN ONSAL [1]

- Titan Umaro [1]

- TITAN-PAMA [1]

- TITEX [1]

- TITEX PLUS [4]

- TITEX, BECK, MAY [1]

- TOKAI [1]

- Tone Fan [1]

- TONGIL [1]

- Tongtai [1]

- TOOLPOWER [8]

- TOPPER [1]

- ToRen [21]

- TORNOS [11]

- TORNOS-BECHLER [2]

- TOS [82]

- TOS - KURIM [1]

- TOS / MAS [1]

- TOS HOL-MONTA [1]

- TOS KURIM [2]

- Tos Varnsdorf [1]

- TOS Warnsdorf [1]

- TOS-CETOS [1]

- TOS-KURIM [1]

- TOS-VARNSDORF [2]

- TOS/BLANSKO [1]

- TOSHIBA [3]

- TOSHIBA-SHIBAURA [1]

- TOSOKU [2]

- TOX [1]

- TOX PRESSOTECHNIK [3]

- TOX-Pressotechnik [4]

- TOYODA [6]

- TRAK [1]

- TRANSFLUID [2]

- TRAUB [12]

- TRENNJAEGER [7]

- TRENNJÄGER [1]

- TRENS [1]

- TRIMILL [1]

- TRIPAN [112]

- TRIPET [1]

- Tronzadoras [1]

- TRUMPF [106]

- TRUMPF 3 D [1]

- TRUMPF TRUMATIC [2]

- TSCHUDIN [6]

- TSUGAMI [3]

- TTMC [1]

- TUGRA [3]

- TUMAC [1]

- TURBO VACUUMENTATION [1]

- TURNIER [1]

- Tuwei [1]

- TUWI [1]

- TVB [1]

- TÜNKERS [1]

- UCIMU [1]

- UDSSR [1]

- Uhrhan & Schwill [2]

- ULMER [1]

- ULMIA [1]

- Ultra [1]

- UMA - SZM [1]

- UNBEK. [1]

- UNBEKAANT [1]

- UNBEKANNT [225]

- Unbekannt/unknown [8]

- UNGERER [6]

- Unicum [1]

- Unimax [2]

- UNION [32]

- UNION-BIELEFELD [3]

- UNIQUE [1]

- UNISIGN [8]

- UNITECH [2]

- UTAS [1]

- Uttis [1]

- UVA [1]

- UWM [27]

- V-TRADE [1]

- V.S.F [3]

- Van de Graaf [5]

- Van Der Graaf [1]

- Van Voorden [1]

- VDF [4]

- VDF BOEHRINGER [5]

- VDF H & H [1]

- VDF HEIDENREICH & HARBECK [2]

- VDF- BOEHRINGER [1]

- VDF-BOEHRINGER [10]

- VDF-HEIDENREICH & HARBECK [2]

- VDF-WOHLENBERG [1]

- VEB [3]

- VEB Blema Gotha [1]

- VEB MIKROMAT [1]

- VEB, BAD- SALZUNGEN [1]

- VEB-MIKROMAT [1]

- Vector [1]

- Veenstra [1]

- Vermtl. Kabbert [1]

- Vermutl. BOSCHERT [1]

- VERNIER [2]

- VERNIER GSP TRENS [1]

- VICTOR [12]

- VIDEOJET [1]

- VIGANO/RIVA [1]

- Viking [2]

- VIPER [1]

- VITAX [2]

- VOEST - ALPINE STEINEL [1]

- VOEST ALPINE [1]

- VOEST- ALPINE [1]

- VOEST-ALPINE [3]

- VOEST-ALPINE STEINEL [3]

- VOEST-ALPINE-WEIPERT [1]

- VOGEL [2]

- VOGTLAND [2]

- VOJUS [1]

- VOLLMER [2]

- VOMA [1]

- VON ARX [1]

- VOUMARD [4]

- Vremac [1]

- VSF [1]

- W. Paul Müller [1]

- W.Z [1]

- WABAMA [1]

- WACHTLER [1]

- WAFIOS [1]

- WAGNER [12]

- WAHLI [1]

- WALDRICH COBURG [4]

- WALDRICH SIEGEN [1]

- WALDRICH-COBURG [17]

- WALDRICH-SIEGEN [7]

- Wallecan [1]

- WALTER [57]

- WANDERER [3]

- WANZKE [5]

- WAX [1]

- Weber [3]

- WEBO [11]

- Webster & Bennett [1]

- WECON [1]

- WEDEVAG [1]

- WEDI PRESSTA 7000 [1]

- WEELABRATOR [1]

- Wegoma [1]

- WEILER [35]

- WEINBRENNER [8]

- WEINGARTEN [61]

- WEIPERT [6]

- WEISSER [7]

- WEISSER HEILBRONN [4]

- WEISSER-HEILBRONN [2]

- Welca [1]

- WELDING [5]

- WELE [1]

- WEMAS [1]

- WEMHOENER [1]

- WENDT [2]

- WENZEL [1]

- WERNER [1]

- WERNER, FRITZ [1]

- WERNER-WERKE [1]

- WERTH [1]

- WESPA [1]

- WESTPHAL [1]

- WEVERK Karlstadt [1]

- WEWAG ECONOMY [2]

- WEYRAUCH [1]

- WFL [4]

- WFL 5-ACHSEN [2]

- WGW [5]

- WHM [1]

- WIDAX [76]

- WIDAX-HEINLEIN [1]

- WIDIA [4]

- WIEDEMANN [2]

- WIEGER [6]

- Wiesemann MAW [1]

- WILA [1]

- WILHELMSBURGER [3]

- WILKINS & MITCHELL [1]

- WILLEMIN MACODEL [2]

- Winkelbieger [1]

- Winslow [1]

- Wirop [1]

- Wisent [1]

- WISSNER [3]

- WM WORKS [1]

- WMT [73]

- WMTR [1]

- WMW [21]

- WMW GOTHA [1]

- WMW ZERBST [1]

- WMW - WILDAU [1]

- WMW Aschersleben [3]

- WMW GLAUCHAU [1]

- WMW GOTHA [1]

- WMW Heckert [1]

- WMW MAGDEBURG [2]

- WMW Niles [5]

- WMW ZERBST [1]

- WMW- NILES [3]

- WMW-ASCHERSLEBEN [1]

- WMW-BLEMA [1]

- WMW-GOTHA [1]

- WMW-HECKERT [10]

- WMW-MEUSELWITZ [1]

- WMW-MIKROMAT [2]

- WMW-MODUL [4]

- WMW-NILES [2]

- WMW-UNION [1]

- WMW-VEB [1]

- WOELLNER [1]

- WOERNER [2]

- Woeste [1]

- WOHLENBERG [20]

- WOHLENBERG-LÖW [1]

- WOHLHAUPTER [1]

- WOLFF, SOLINGEN [1]

- WOTAN [13]

- WRK [1]

- WSI [1]

- WTO,WNT,EWS [2]

- WUENSCH Systemat [1]

- WUHAN [1]

- WÄLZTECHNIK [5]

- WÖRNER [3]

- XYZ [3]

- YALE [1]

- YAM [1]

- YANG IRON WORKS [1]

- YASDA [1]

- YCM [1]

- ycm SUPERMAX [3]

- Yoga [2]

- YOMIS [1]

- YOMIS - TSUNODA [1]

- YUNNAN [1]

- ZANI [1]

- Zanrosso [1]

- Zattoni [1]

- Zavody Tazkeho Strojarstva [1]

- ZAYER [17]

- ZEISS [1]

- ZERBST [3]

- ZETT - MESS [1]

- ZETTL [2]

- ZEULENRODA [9]

- ZIERSCH & BALTRUSCH [10]

- ZIMMER [30]

- Zimmer+Kreim [1]

- ZIMMERMANN [1]

- ZINSER [3]

- ZJ [2]

- ZMM [31]

- ZMM - SLIVEN [3]

- ZMM / HUVEMA [1]

- ZMM BULGARIEN [1]

- ZOLLER [13]

- ZOPF [19]

- ZPS [3]

- ZPS DEPO [1]

- ZUBEHOER [1]

- Traders

- machine-categorie:

- Metal Processing

- Sheet metal working - shaeres - bending

- Lathes

- machine tools

- Boring mills - Machining Centers - Drilling machines

- Presses

- Milling machines

- Saws

- Grinding machines

- Welding machines

- Gear cutting machines

- Measurement equipment

- Machine tools grinding machines

- Threading machines

- Machining centre

- Stamping press

- Drawbenches

- Measuring machines

- Lapping machines

- Drilling maschines

- Tube & Pipe processing - Tube & pipe manufacturing

- Erosion machines

- Surface finishing

- forging attachments

- Bar processing - Bar manufacturing

- Storing sytems

- Steelprocessing - drilling - burning - notching

- Planing machines

- Spring making - Wire working machines

- Center-drilling machines

- Boring mill

Metal Processing

Machinelist: Metal Processing

Planer-Type Milling M/C - Double Column

- desba TRADING

- Im Hofgarten 6

- 61130 Nidderau

- Deutschland

-

+49 (0)6187 20 30 749

-

info@desba-trading.de

www.desba-trading.de

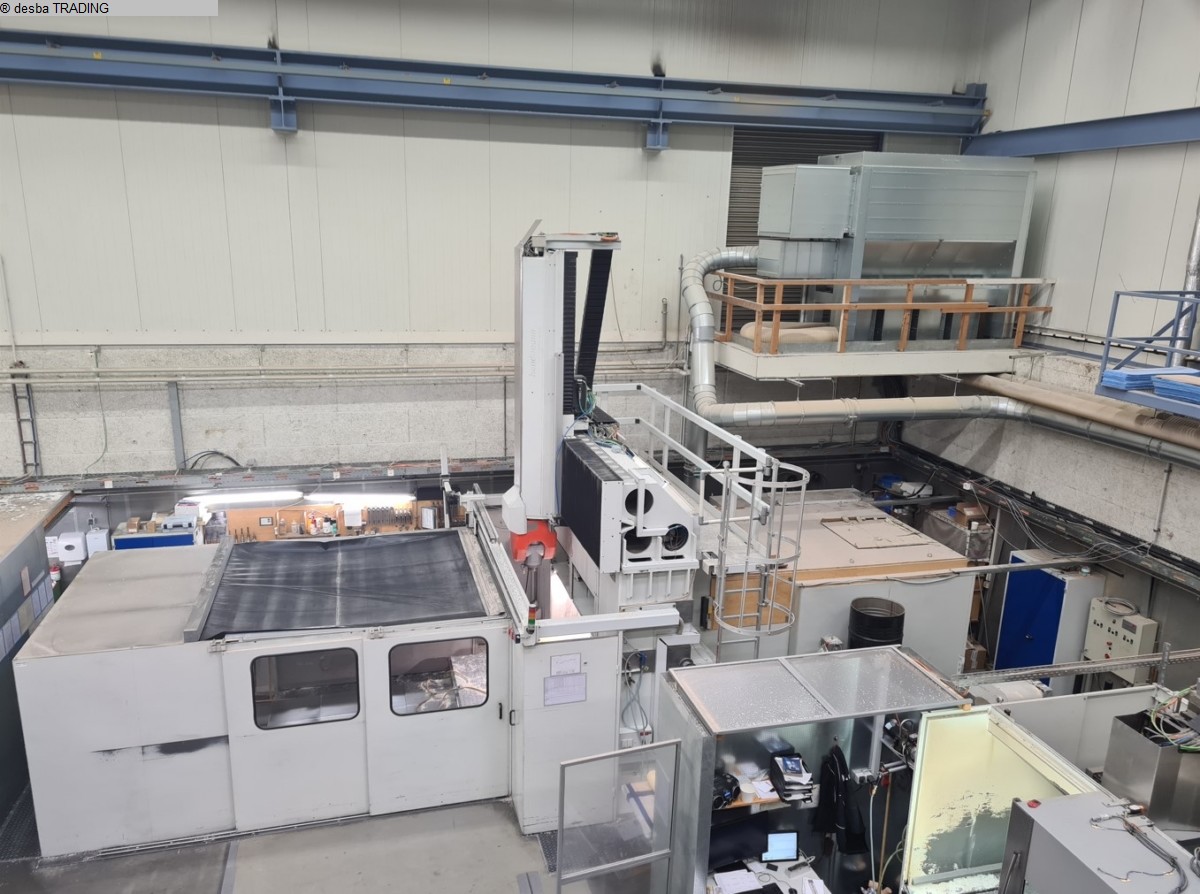

#2072-2053 · Planer-Type Milling M/C - Double Column

HANDTMANN - NT 300 / 220 T - - 2001 - Fidia C20

Technical details

• Traverse paths: X axis approx. 4,200mm, Y axis approx. 2,750mm, Z axis approx 1,650mm, °C axis approx. +/-275° and A axis +95° / -120° • Fixture space: approx. 3,000mm x approx. 2,200mm x approx. 980mm • Table size: 3,000mm x 2,200mm with T-slots in a 150mm grid • Table load: 1,000kg / m² table surface • Working and rapid traverse speed: max. 20m/min • Machine dimensions: length approx. 9,500mm (without housing), width approx. 5,900mm, height approx. 6,400mm (Z axis extended) • Weight: approx. 40,000kg • Controller: Fidia C20 • Spindle: HSK 63 from Fischer (Switzerland), 24,000 rpm (grease lubricated) • Spindle hours: 6,939 hours (as of 05/16/22) • Total hours: 76,793 hours (as of 05/16/22) • Tool changer: 2 tool magazines with 30 tool places each, max. Tool weight 4kg, max. tool diameter 80mm or Ø125mm if no two sister tool places, max. tool length 280mm cover plate pneumatic • Cooling: tool spray device with a container of 19.5 l, spray head with adjustable output 0.04 - max. 2.3l/h • Tool control: Blum Laser • Wireless probe: Manufacturer M&H, type 25.10, year of manufacture 2021 • Exchange ball screw X - axis 10.07.2018. • Telescope cover replaced on February 26, 2019 on one side.

Description :

• Traverse paths:X axis approx. 4,200mm,

Y axis approx. 2,750mm,

Z axis approx 1,650mm,

°C axis approx. +/-275° and A axis +95° / -120°

• Fixture space: approx. 3,000mm x approx. 2,200mm x approx. 980mm

• Table size: 3,000mm x 2,200mm with T-slots in a 150mm grid

• Table load: 1,000kg / m² table surface

• Working and rapid traverse speed: max. 20m/min

• Machine dimensions: length approx. 9,500mm (without housing), width approx.

5,900mm, height approx. 6,400mm (Z axis extended)

• Weight: approx. 40,000kg

• Controller: Fidia C20

• Spindle: HSK 63 from Fischer (Switzerland), 24,000 rpm (grease

lubricated)

• Spindle hours: 6,939 hours (as of 05/16/22)

• Total hours: 76,793 hours (as of 05/16/22)

• Tool changer: 2 tool magazines with 30 tool places each, max.

Tool weight 4kg, max. tool diameter 80mm or Ø125mm if no

two sister tool places, max. tool length 280mm cover plate

pneumatic

• Cooling: tool spray device with a container of 19.5 l, spray head

with adjustable output 0.04 - max. 2.3l/h

• Tool control: Blum Laser

• Wireless probe: Manufacturer M&H, type 25.10, year of manufacture 2021

• Exchange ball screw X - axis 10.07.2018.

• Telescope cover replaced on February 26, 2019 on one side.

Machining Center - Vertical

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S2019 · Machining Center - Vertical

HANDTMANN - UBZ NT 300 / 220 T - - 2001 - Fidia C20

Technical details

Handtmann NT 300 / 220 T: - Year of construction: 2001 - Traverse paths: X - axis approx. 4,200mm, Y - axis approx. 2,750mm, Z - axis approx. 1,650mm, °C axis approx. +/-275° and A axis +95° / -120° - Fixture space: approx. 3,000mm x approx.2,200mm x approx.980mm - Table size: 3,000mm x 2,200mm with T-slots in a 150mm grid - Table load: 1,000kg / m² table surface - Working and rapid traverse speed: max. 20m/min - Controller: Fidia C20 - Spindle: HSK 63 from Fischer (Switzerland), 24,000 rpm (grease lubricated) - Spindle hours: 6,939 hours (as of 05/16/22) - Total hours: 76,793 hours (as of 05/16/22) - Tool changer: 2 tool magazines with 30 tool places each, max. - - Tool weight 4kg, max. tool diameter 80mm or Ø125mm if no two sister tool places, max. tool length 280mm cover plate pneumatic - Cooling: tool spray device with a container of 19.5 l, spray head with adjustable output 0.04 - max. 2.3l/h - Tool control: Blum Laser - Wireless probe: Manufacturer M&H, type 25.10, year of construction 2021 - Exchange ball screw X - axis 10.07.2018 - Telescope cover 26.02.2019 exchanged on one side Machine dimensions: Length approx. 9,500mm (without housing) Width approx. 5,900mm Height approx. 6,400mm (Z axis extended) Weight: approx. 40,000kg

Description :

Handtmann NT 300 / 220 T:- Year of construction: 2001

- Traverse paths: X - axis approx. 4,200mm, Y - axis approx. 2,750mm, Z - axis

approx.

1,650mm, °C axis approx. +/-275° and A axis +95° / -120°

- Fixture space: approx. 3,000mm x approx.2,200mm x approx.980mm

- Table size: 3,000mm x 2,200mm with T-slots in a 150mm grid

- Table load: 1,000kg / m² table surface

- Working and rapid traverse speed: max. 20m/min

- Controller: Fidia C20

- Spindle: HSK 63 from Fischer (Switzerland), 24,000 rpm (grease lubricated)

- Spindle hours: 6,939 hours (as of 05/16/22)

- Total hours: 76,793 hours (as of 05/16/22)

- Tool changer: 2 tool magazines with 30 tool places each, max. - -

Tool weight 4kg, max. tool diameter 80mm or Ø125mm if no

two sister tool places, max. tool length 280mm cover plate

pneumatic

- Cooling: tool spray device with a container of 19.5 l, spray head

with adjustable output 0.04 - max. 2.3l/h

- Tool control: Blum Laser

- Wireless probe: Manufacturer M&H, type 25.10, year of construction 2021

- Exchange ball screw X - axis 10.07.2018

- Telescope cover 26.02.2019 exchanged on one side

Machine dimensions:

Length approx. 9,500mm (without housing)

Width approx. 5,900mm

Height approx. 6,400mm (Z axis extended)

Weight: approx. 40,000kg

Used Machines Request / Contact

Used Machines Request / Contact

Metalworking comprises a variety of applications involving the manipulation of metal from large-scale production of metals including lathing milling and cutting to smaller operations such as jewellery working. No matter the application used metal processing machines present an ideal way of obtaining the equipment you need at a price you can afford. Used metal processing machines such as milling machines can be manually operated or using computer numeric control which increases the overall precision of the machine. The type of used metal processing machines you need depends on the applications you use but at LagerMaschinen.de you are sure to find what you’re looking for.

The right machine for every field of applicationUsed metal processing machines can be used in several fields. Companies active in the computer industry can obtain used metal processing machines for circuit board soldering and companies that need to bond different pieces can find the welding machines that they need. If your company is in the business of making the precision parts needed to make other precision machines then used grinding machines can be a great way to expand or refurbish your production lines. Used metal processing machines can also be found for lathing drilling milling and several other uses.

Used equipment from LagerMaschinen.deNo matter the type of equipment you will find the used metal processing machines you need at LagerMaschinen.de. With its international network of suppliers this platform can provide you with the used metal processing machines you need at a price you can afford.