CNC Lathe

Machinelist: CNC Lathe

CNC Lathe

- MAMACH Machinenhandel BV

- Campagneweg 10

- 4761 RM Zevenbergen

- Niederlande

-

+31 (0)168325354

-

info@mamach.nl

www.mamach.nl

#2041-V2453 · CNC Lathe

TORNOS - EvoDECO 16/10 - - 2017 - Fanuc 31i-B5

Technical details

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

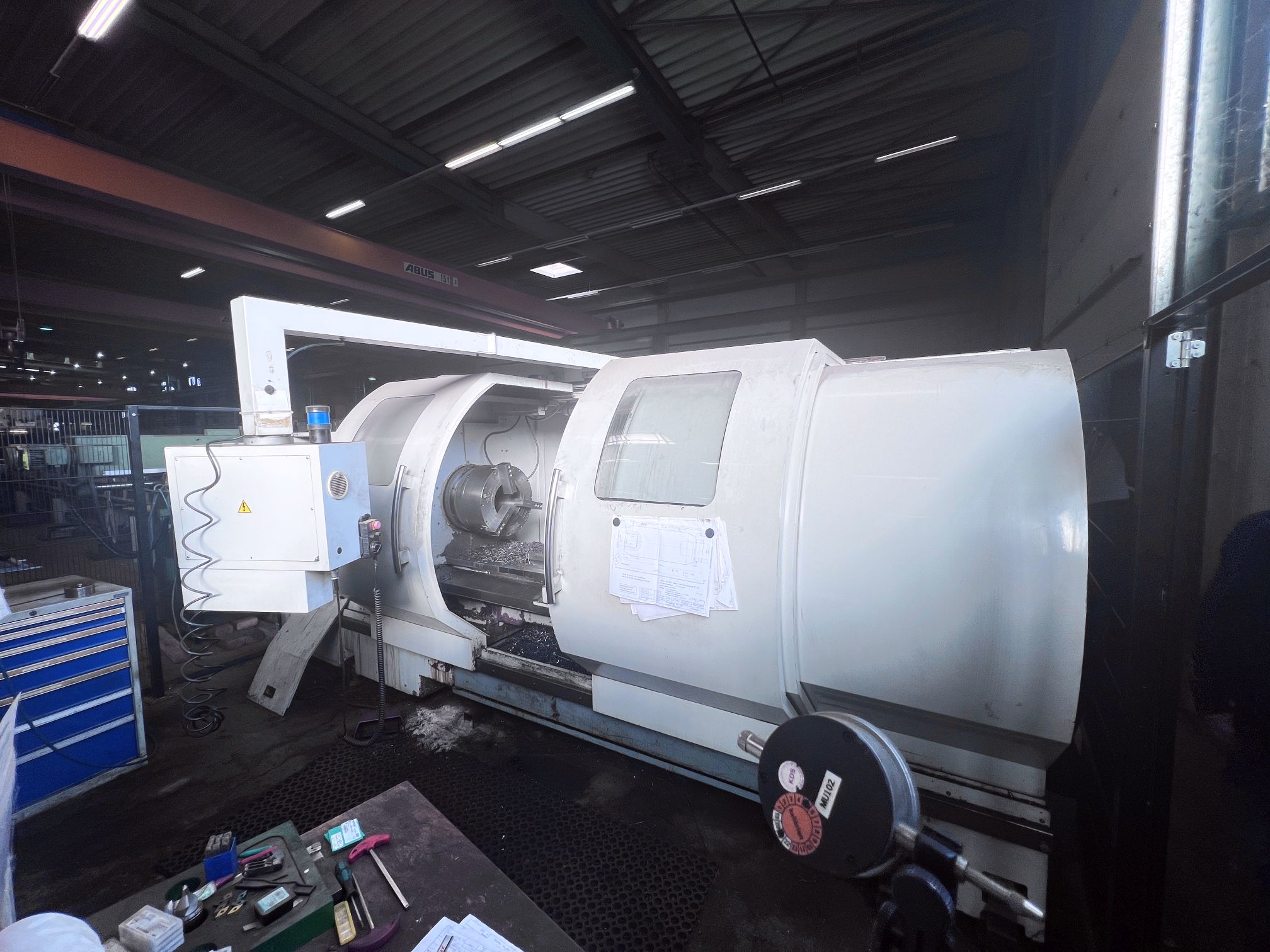

#1048-746757 · CNC Lathe

MICROTURN - Challenger BNC-3080 - - 2008 - FAGOR 8055

Technical details

Technical description : CNC Pipe-thread-lathe with big spindle bore diameter. Two chucks on each side ( left and right ) of spindle box. Main chuck: SCHUNK ROTA EP 500-260, 3 jaw chuck. Turning diameter above bed = 760 mm. Turning diameter above cross slide = 420 mm. Working hours = 16936 h, mid November 2022

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-746758 · CNC Lathe

MICROTURN - Challenger BNC-3080 - - 2008 - FAGOR 8055

Technical details

Technical description : CNC Pipe-thread-lathe with big spindle bore diameter. Two manual clamping chucks on each side ( left and right ) of spindle box. Main chuck: SCHUNK ROTA S-PLUS 630-252, 3 jaw chuck. Turning diameter above bed = 760 mm. Turning diameter above cross slide = 420 mm. Working hours = 14050 h, mid November 2022

When mass-producing a tool part or complete product absolute accuracy is key. With Computer Numerical Control - CNC - accuracy is now guaranteed and no longer dependent on human control. CNC lathes have replaced conventional lathes in the last few years particularly regarding products where measurements must be absolutely uniform as a matter of safety. Exact specifications and measurements are loaded into the machine as a data file and after a trial run pieces are cut with complete precision while under the supervision of a CNC lathe operator. In this way CNC lathes are guaranteed to last for many years as the heavy physical strain put on normal lathe machines is not the case here. CNC lathes can be extremely expensive when bought new but now with LagerMaschinen you can still outfit your business with a CNC lathe without overstepping your company budget.

Purchase a used CNC lathe with LagerMaschinenLagerMaschinen has developed several features in the last few years designed to optimize your purchasing experience. Its online platform cross-references used machines based on location specifications and price. Communicate with current owners and experts in your field to find the best used CNC lathes for your business needs. Additionally LagerMaschinen's delivery and installation services will save you time money and frustration. LagerMaschinen prides itself on providing a practical and affordable business solution for businesses that need to find reliable used machinery. Find the perfect used CNC lathes today with LagerMaschinen.

TOP Manufacturer:

MAZAK - KRAFT - MORI SEIKI - GILDEMEISTER - INDEX - COLCHESTER - PINACHO - OKUMA - NAKAMURA - GEMINIS -