Milling machines

Machinelist: Milling machines

Bed Type Milling Machine - Universal

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91036 · Bed Type Milling Machine - Universal

KRAFT - BFM 2000 - - Fabrikneu - HEIDENHAIN 640i TNC

Technical details

TRADE TERM : F.O.B. TAIWAN PORT SHIPMENT : WITHIN 14 DAYS AFTER RECEIPT OF YOUR DOWN PAYMENT PAYMENT : 30% DOWN PAYMENT BY SWIFT TRANSFER, 70% BY IRREVOCABLE & SIGHT L/C IN OUR FAVOR PACKING : BY SEAWORTHY PACKAGE WARRANTY: 12 MONTHS VALIDITY : 60 DAYS

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91021 · Bed Type Milling Machine - Universal

KRAFT - UH-1000 - - Fabrikneu - oder Siemens/Fanuc/Heidenhain

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91785 · Bed Type Milling Machine - Universal

KRAFT - BM 2200 - - Fabrikneu -

Technical details

Features of bed type milling machine ? Servo motors drive for X, Y, Z three axes ? Handwheel can be equipped for easy tool setting and smoothly axis moving ? Robust & rugged machine body made of high grade casting assuring superb stability and long lasting life. ? Fine elaborate workmanship with great care and neat appearance with perfect paint finish. ? Precision-ground guideways with hardened surface for long-term accuracy and wear-resistance. ? preloaded ball screw with zero backlash for easy and precise feeds ? simultaneous axis movement ? Turcite-B coated guides ? swivelling control panel, fully equipped with all operating controls ? automatic lubrication ? spindle brakes ? equipment according to CE ? Large work area of 500x2200mm and up to 1200 kg table load capacity. ? Vertical universal head rotates 360° for versatile cutting performance. ? High speed vertical universal head for robust & heavy cutting performance. ? Separate button for rapid traverse of axes, aside automatic feeding, for easier operation and less idle time. ? Compulsory lubrication of horizontal milling spindle transmission gears for smooth running. ? Modular design with wide options for diverse needs: 2-axis DRO unit, 3-axis DRO unit, table guards, spindle guards, indexing dividing heads, various clamping kits, vices, tool holders, etc.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

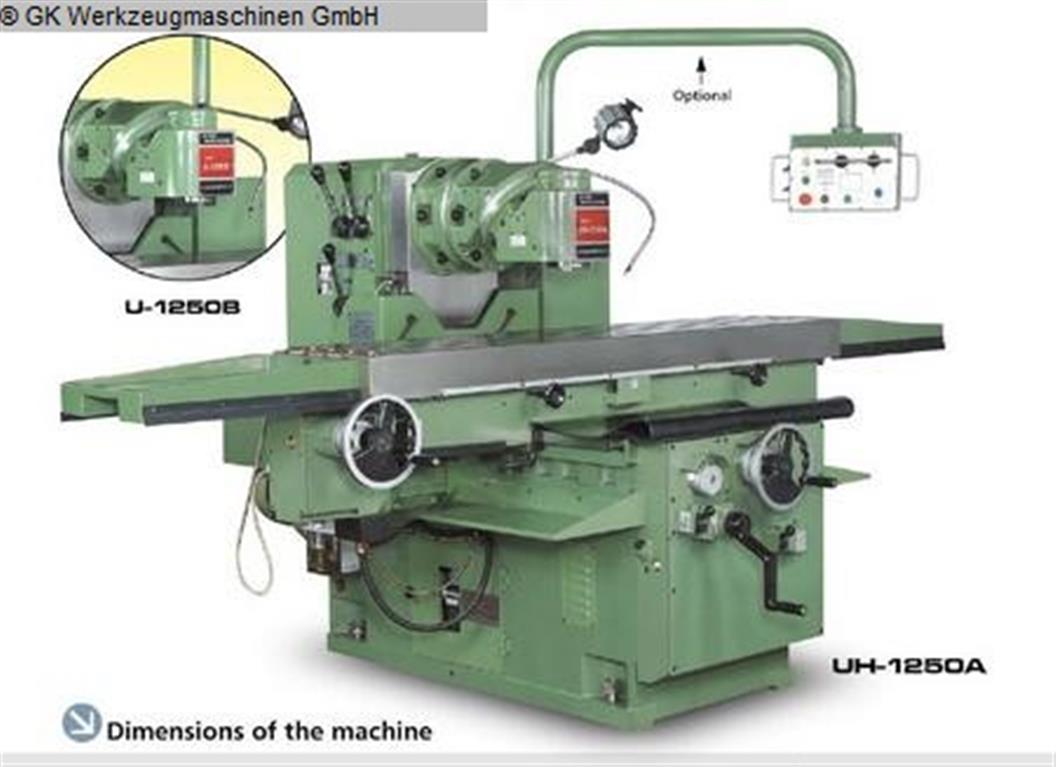

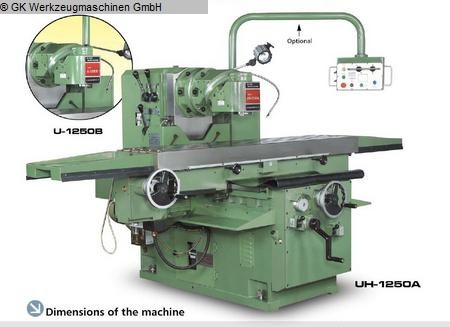

#4019-91020 · Bed Type Milling Machine - Universal

KRAFT - UH-1250 - - Fabrikneu - oder Siemens/Fanuc/Heidenhain

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91037 · Bed Type Milling Machine - Universal

KRAFT - BFM 2600 - - Fabrikneu - HEIDENHAIN 640i TNC

Technical details

TRADE TERM : F.O.B. TAIWAN PORT SHIPMENT : WITHIN 14 DAYS AFTER RECEIPT OF YOUR DOWN PAYMENT PAYMENT : 30% DOWN PAYMENT BY SWIFT TRANSFER, 70% BY IRREVOCABLE & SIGHT L/C IN OUR FAVOR PACKING : BY SEAWORTHY PACKAGE WARRANTY: 12 MONTHS VALIDITY : 60 DAYS

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91035 · Bed Type Milling Machine - Universal

KRAFT - BFM 1500 - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

TRADE TERM : F.O.B. TAIWAN PORT SHIPMENT : WITHIN 14 DAYS AFTER RECEIPT OF YOUR DOWN PAYMENT PAYMENT : 30% DOWN PAYMENT BY SWIFT TRANSFER, 70% BY IRREVOCABLE & SIGHT L/C IN OUR FAVOR PACKING : BY SEAWORTHY PACKAGE WARRANTY: 12 MONTHS VALIDITY : 60 DAYS

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91038 · Bed Type Milling Machine - Universal

KRAFT - BFM 3000 - - Fabrikneu - HEIDENHAIN 640i TNC

Technical details

TRADE TERM : F.O.B. TAIWAN PORT SHIPMENT : WITHIN 14 DAYS AFTER RECEIPT OF YOUR DOWN PAYMENT PAYMENT : 30% DOWN PAYMENT BY SWIFT TRANSFER, 70% BY IRREVOCABLE & SIGHT L/C IN OUR FAVOR PACKING : BY SEAWORTHY PACKAGE WARRANTY: 12 MONTHS VALIDITY : 60 DAYS

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91039 · Bed Type Milling Machine - Universal

KRAFT - BFM 4000 - - Fabrikneu - HEIDENHAIN 640i TNC

Technical details

TRADE TERM : F.O.B. TAIWAN PORT SHIPMENT : WITHIN 14 DAYS AFTER RECEIPT OF YOUR DOWN PAYMENT PAYMENT : 30% DOWN PAYMENT BY SWIFT TRANSFER, 70% BY IRREVOCABLE & SIGHT L/C IN OUR FAVOR PACKING : BY SEAWORTHY PACKAGE WARRANTY: 12 MONTHS VALIDITY : 60 DAYS

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-291118 · Bed Type Milling Machine - Universal

KRAFT - BFM 3000 - - 2020 - HEIDENHAIN 640i TNC

Technical details

TRADE TERM : F.O.B. TAIWAN PORT SHIPMENT : WITHIN 14 DAYS AFTER RECEIPT OF YOUR DOWN PAYMENT PAYMENT : 30% DOWN PAYMENT BY SWIFT TRANSFER, 70% BY IRREVOCABLE & SIGHT L/C IN OUR FAVOR PACKING : BY SEAWORTHY PACKAGE WARRANTY: 12 MONTHS VALIDITY : 60 DAYS

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100559 · Bed Type Milling Machine - Universal

MTE - K20 - - 2016 - HEIDENHAIN TNC-530

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100453 · Bed Type Milling Machine - Universal

SORALUCE - TA 35 - - 2009 - HEIDENHAIN TNC-530

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-1000504 · Bed Type Milling Machine - Universal

Soraluce - TA-35 - - 2009 - Heidenhain iTNC 530

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100563 · Bed Type Milling Machine - Universal

Anayak - VH Plus 3000 MG - - 2008 - HEIDENHAIN TNC-530

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-1000335 · Bed Type Milling Machine - Universal

CORREA - CF22/25 - - 2007/2023 - Heidenhain TNC 530

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100510 · Bed Type Milling Machine - Universal

CORREA - Diana 35 - - 2007/2023 - HEIDENHAIN TNC-i530

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-10028 · Bed Type Milling Machine - Universal

CORREA - CF22/25-Plus - - 2004/2023 - Heidenhain TNC 426

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100503 · Bed Type Milling Machine - Universal

MTE - BF 4200 - - 2004 - Heidenhain TNC 530

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100459 · Bed Type Milling Machine - Universal

SACHMAN - T 22 - - 2003 - HEIDENHAIN TNC-430

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-10027 · Bed Type Milling Machine - Universal

CORREA - CF17T - - 2003 - HEIDENHAIN TNC-426

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100433 · Bed Type Milling Machine - Universal

CORREA - A30/30 - - 2001/2023 - Heidenhain TNC 426

Technical details

Overhauled universal milling machine Correa A30 with Heidenhain control 415 Other technical specifications and accessories, as defined in Appendix. Other special options to retrofit. Images machine in the overhaul. Warranty: 6 months on parts Take advantage of the favorable leasing and rental conditions of ABC Leasing. Ask us about it. Of course, you will get the free delivery, installation / commissioning and operational hand-over and control training. The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100454 · Bed Type Milling Machine - Universal

ANAYAK - VH 2200 - - 1998/2023 - HEIDENHAIN TNC-426

Technical details

used universal bed type milling machine with chip conveyor, automatic 2 position (vertical/horizontal) head 3000Rpm The retrofitting jobs done in this machine, are the same than those done to all of our machines. - Completely repair of the head, replacing bearings, shafts and engaging gears. - Completely replacement of all the bearings of the machine. - Replacing the joining screws of the bodies. - Completely repair of spindles. - Adjustment and repair of axis. - Grinding and adjusting all guides, because of deterioration. - Grinding and adjusting of the guide ways of the ram. - Repairing or grinding of the saddle. - Repairing ram. To replace the bearings and damaged elements. - Repairing of the three (3) ballscrews. - Inspection and repair of all the motors of the machine, as well as of all the electrical installation and electrical controls, included Numerical Control CNC. - The machine has been completely painted. - Repair of side casings, assembling of EC guarding. - Spindle positioning: encoder M19 - Laser interferometer

Double Column Milling M/C - Gantry Type

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

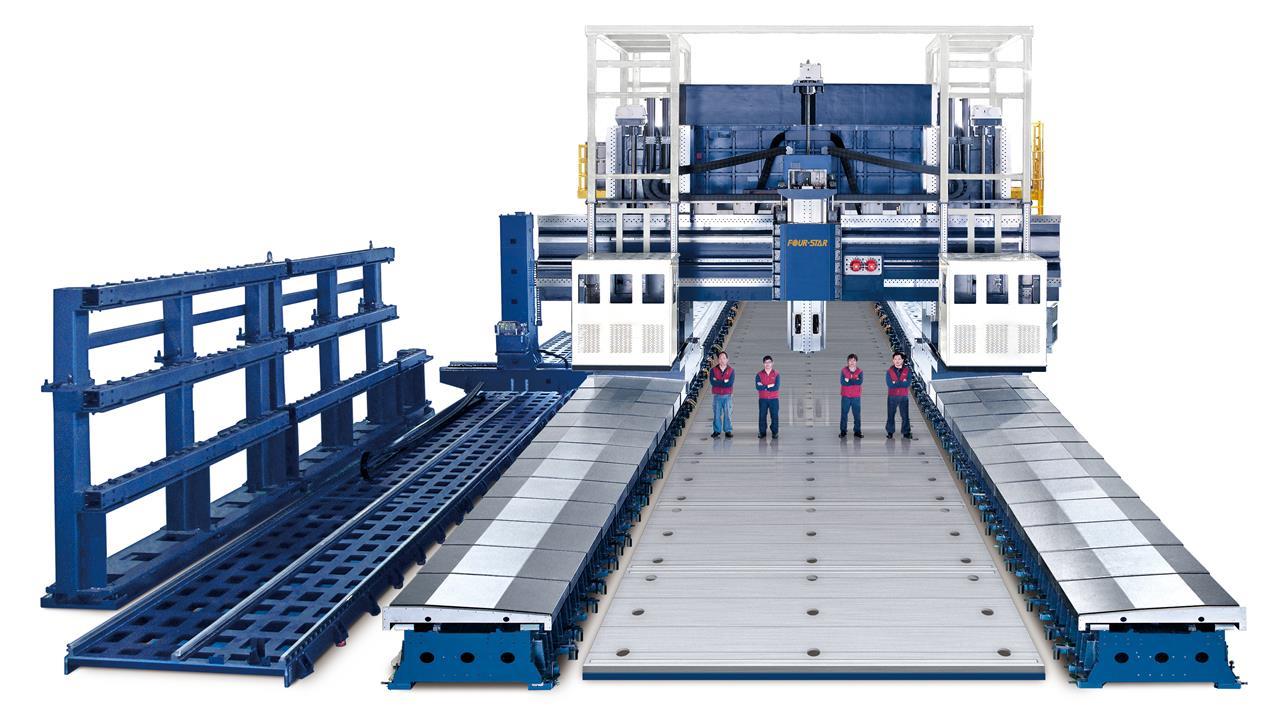

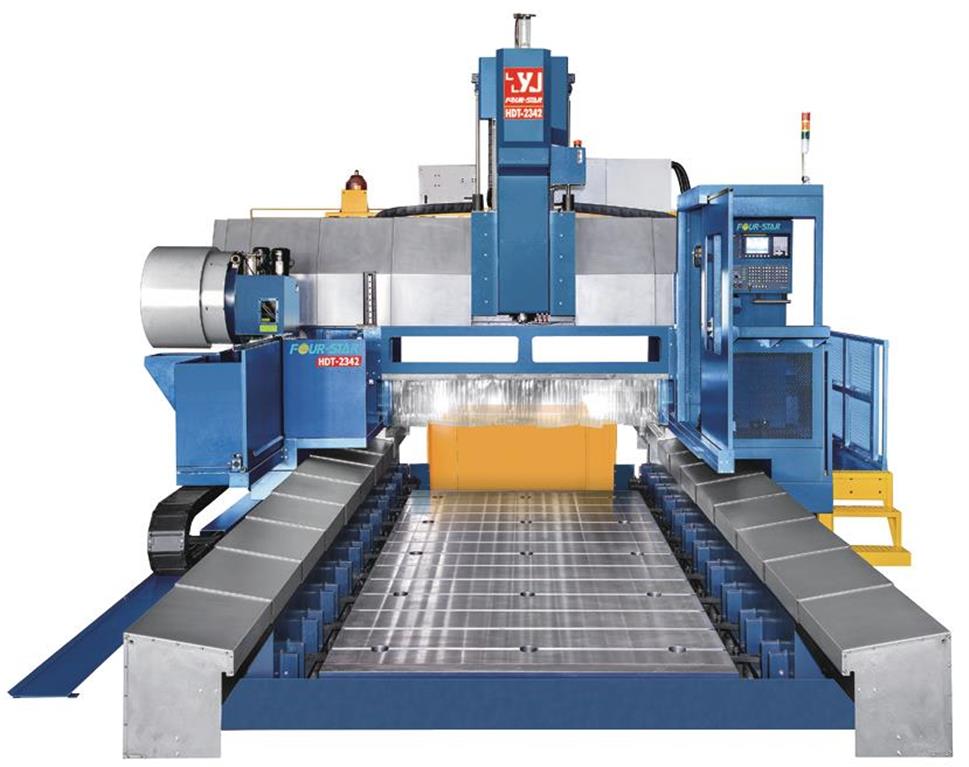

#4019-98120 · Double Column Milling M/C - Gantry Type

KRAFT - SD(W)-36|SD(W)-42|SD(W)-48|SD( - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-98105 · Double Column Milling M/C - Gantry Type

KRAFT - SD(W)-24|SD(W)-28|SD(W)-32 - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-98125 · Double Column Milling M/C - Gantry Type

KRAFT - HDT-18|HDT-21|HDT-24 - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

Milling machines are exceptionally versatile tools used to machine a variety of materials, such as metals, woods and synthetics. Milling machines come in a range of sizes from small portable models for home hobbyists to large-scale industrial milling machines for factories. Whether you are looking for vertical or horizontal milling machines, manually operated or computer numerically controlled (CNC), you can find exactly what you need quickly and easily at LagerMaschinen.

Which milling machine is the best for you?Milling machines are generally classified based on the main spindle's orientation. Horizontal milling machines are best suited to heavy materials, bulky or unconventional shaped work pieces, while vertical milling machines offer more advantages for design work and precision cutting. Although some prefer the level of control offered by manually or even mechanically operated machines, some businesses require the efficiency afforded by CNC machines. Regardless of which milling machines best suit your needs, you can find a wide array of used machines at LagerMaschinen.

Online shopping has never been so easyLagerMaschinen offers users a number of distinct advantages. In this day and age, shopping online is a practical solution to strains on a busy schedule. You can browse quickly and easily online, anytime day or night, from the comfort of home or office. Also at LagerMaschinen, you can sort all your searches by price, location or specific brands to save yourself time and money in comparative shopping. From milling machines to grinders to drill presses, you can find the best selection of used machines on the web at LagerMaschinen.