Optical Profile Grinding Machine

Machinelist: Optical Profile Grinding Machine

Grinding Machine - Centerless

- Marcels Maschinen AG

- Anthoptstrasse 11

- 8222 Beringen (Schaffhausen)

- Schweiz

-

(0041) 44 872 3400

(0041) 44 872 3403 -

info@marcels-maschinen.ch

http://www.marcels-maschinen.ch

#1065-4927 · Grinding Machine - Centerless

DANOBAT ESTARTA - 301 MV - - 2011 -

Technical details

Datasheet

Request / Contact

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19717 · Grinding Machine - Centerless

PETEWE - SLR 250 E CNC - - 1988 - Siemens Sinumerik 3

Technical details

max.workpiece length for plunge-cut grinding 250 mm max.workpiece length for throughfeed grinding 300 mm grinding wheel size: diam. x width 600 x 250 mm regulating wheel size: diam. x width 350 x 250 mm grinding speed 35 / 45 / 60 m/sec. regulating wheel speed stfl. 8- 100 rpm (360 rpm) control wheel slide swivels + 2 to - 7° grinding wheel drive 22 kW total drive 35 kW equipped with: - Standard version with double bearing mounted grinding spindle and control spindle. - SIEMENS CNC control type Sinumerik 3 for control of all feeds, speeds and dressing programs. For rapid traverse approach, roughing, finishing, fine finishing and spark out, all feed and time values can be programmed. - The dressing speeds and dressing amounts as well as the number of workpiecesper dressing operation can also be programmed. number of workpieces per dressing operation can be entered directly into the control. - Electric handwheel for manual traverse of all axes - 2-axis CNC profiling and dressing device for the grinding wheel, - Copy dressing device for the regulating wheel via ruler. - Single-indexing workpiece support block built up with devices for the manual swiveling in and out of workpieces, fixtures for different workpiece lengths - DITTEL automatic balancing device for the grinding wheel - regulating wheel slide swivels and rotates with infinitely variable drive of the regulating wheel

Datasheet

Request / Contact

- STEINHAND GmbH

- Am Stahlwerk 15

- 45527 Hattingen

- Deutschland

-

+49 (0) 2324 / 977 26 - 01

+49 (0) 2324 / 977 26 - 99 -

info@steinhand.de

www.steinhand.de

#2026-1614 · Grinding Machine - Centerless

LIDKOEPING - CL 520 - - 1987 -

Technical details

Centerless Grinding Machine | Lidkoping 520 Equipped with: - 1 Electrobalance system - 1 CNC plunge on the working wheel - 1 CNC drive motor on the control grinding wheel - Automatic pass on the workung wheel diamond cutter - 2 hydraulic diamond cutters - 1 Ruler holder for working in a row The machine is in a well contained condition. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #Tags: CL520 | CL-520

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-727772 · Grinding Machine - Centerless

KOENIG & BAUER - MULTIMAT 150-5 - - 1978 -

Technical details

K O E N I G & B A U E R (Germany) Centreless Grinder with Plunge-in Grinding Device Model Multimat 150 - 5 Year approx. 1978 S/Nr. 73 918 _______________________________________________________ Grinding Ø regular/maximal 2 – 50/100 mm Max. length of workpiece for Thru-Feed-grinding 250 mm Max. length of workpiece for plunge-cut grinding 200 mm Grinding wheel size, Ø x width 600 x 200 mm Regulating wheel size, Ø x width 300 x 200 mm Grinding wheel speed, max. 1.450 rpm/35 m/sec. Regulating wheel speeds (stepless) 10 – 140/230 rpm Regulating wheel tilt plus/minus +3 / –5 ° Stroke of Dressing Device 200 mm Grinding wheel drive, approx. 18,5 kW Total electrical load approx.. 25 kW - 380 V - 50 Hz Weight approx.. 4.500 kg Accessories/Special Features: * Machine is suitable for a Plunge-In Grinding Process with a manual workpiece Injection device and a pneumatic driven workpiece lift-off device after grinding Process. The final removal of the finished parts is by hand. * Actually mounted a workpiece rest for medium sized workpieces, (maybe 50 mm) * The Regulating wheel slide/workpiece rest carriage can be inclinate by 3 to 5 degrees to compensate cylindrical errors. * The infeed adjustment of workpiece saddle is controlled by a hydraulic plunge-in device with a cam device for quick-feed forward and backwards, also there is a fine infeed actuated by a step motor controlled by MARPOSS – Unit. * The grinding spindle unit is fixed and accommodates a complex hydraulic dressing device with template and the slide can be swivelled for profiling plane shoulders, stepmotor for the infeed of diamond tool compensation, also there is mounted a hi pressure coolant nozzle to cool down the diamond tool and to rinse the grinding wheel. * Hydraulic driven Copy Dressing device mounted above the regulating wheel. * The regulating wheel speed is steplessly adjustable, higher speed during dressing poc. * The control panel contains all machine functions like Numbers of dressing cycles, number of workpieces, adjustable spark-out time, speed range, manual or automatic process, etc. * some sep. Flanges and grinding and regulating wheels, tool for changing the flanges,separate Hydraulic and sep. Switch cabinet, central lubrication, MARPOSS Unit, * ! Actually there is no Coolant device available ! Condition : Good to very good. Machine can be inspected under power. Ideal for small batch production. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

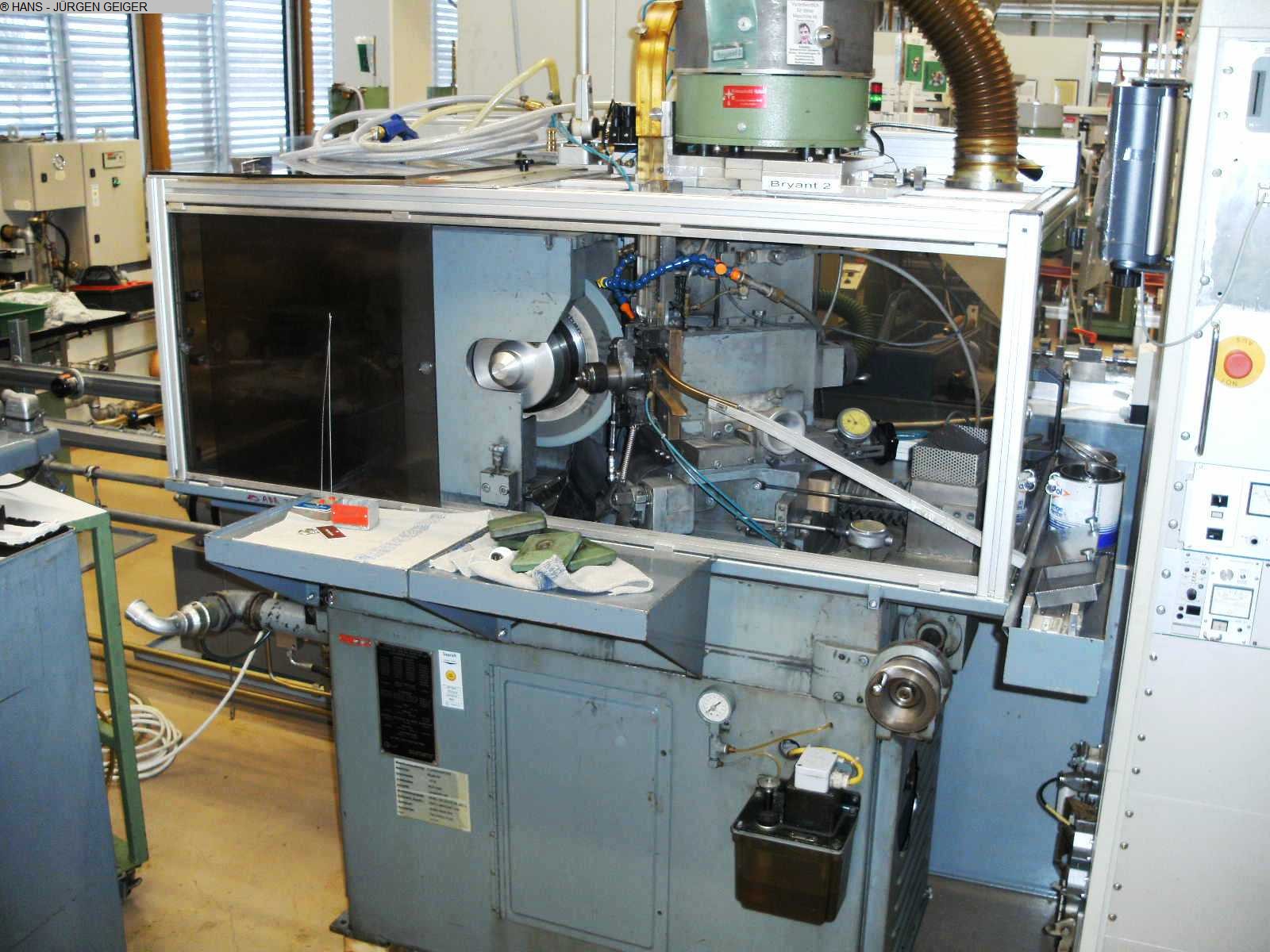

#1049-491377 · Grinding Machine - Centerless

BRYANT - 45 M / Serial No. B 16049 - - 1973 -

Technical details

- MW-MACHINES

- Dorf 9

- 4133 Hofkirchen

- Österreich

-

+43 (0)66718068977

- -

info@machines-mw.at

machines-mw.at

#2077-10012 · Grinding Machine - Centerless

LIDKOEPING - 3B - - - -

Technical details

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-24002 · Grinding Machine - Centerless

NOMOCO - M 100 - - -

Technical details

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-24036 · Grinding Machine - Centerless

KOENIG & BAUER - Multimat 150/6 - - -

Technical details

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-24001 · Grinding Machine - Centerless

NOMOCO - M 100 - - -

Technical details

Optical Profile Grinding Machine

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17777 · Optical Profile Grinding Machine

BLOHM - Profimat MC 610 S - - 2012 - SINUMERIK 840 D

Technical details

5 Axis Profile grinding machine, with SIEMENS SIN840D, double dividing head (B-C axis), V-axis (coolant nozzles), EROWA tool changing device (machine can also be operated without a tool changer), fire extinguishing device, Renishaw probe prepared without coolant device - was connected to the central supply.

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17698 · Optical Profile Grinding Machine

BLOHM - Profimat MC 610 S - - 2010 - SINUMERIK 840 D

Technical details

5 Axis Profile grinding machine, with SIEMENS SIN840D, double dividing head (B-C axis), V-axis (coolant nozzles), EROWA tool changing device (machine can also be operated without a tool changer), fire extinguishing device, Renishaw probe prepared without coolant device - was connected to the central supply.

Datasheet

Request / Contact

- SKM Industriemaschinen

- Röntgenstr. 3

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 954 986 0

+49 (0) 7309 954 986 1 -

info@skm-maschinen.de

www.skm-maschinen.de

#2032-1751 · Optical Profile Grinding Machine

JUNG - JE 525P - - 2007 - Touch / Siemens

Technical details

including table dresser with folding function Includes magnetic plate 500 x 200 mm including coolant system with band filter including work light Includes grinding wheel with holder including machine feet including documentation Surface grinding and profile grinding with one machine. Simple, manual setup of the machine is controlled via electronic handwheels/joystick. Grinding and profile dressing are set via the touchscreen operator guidance.

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-15990 · Optical Profile Grinding Machine

ABA - Powerline - - 2001-2023 - SINUMERK 840 D

Technical details

Equipment and accessories - Linear measuring systems in Y- and Z-axis - All linear axes with digital servo motors and ball screw drive - Belt filter system with paper belt filter, tank capacity 640 l, coolant pump 200 l/min/4 bar - Manual coolant nozzles - adjustable - Automatic working chamber door pneumatically controlled - Electro-permanent magnetic plate 800 x 500 mm, pendulum pole pitch 18 mm - Automatic grinding wheel balancing device Fa. MPM - Full enclosure of the working area in stainless steel partial execution with LED working area lighting - Manually operated door, safety interlock in automatic mode - Portable electronic handwheel in automatic and manual mode for all axes - Three-color signal light - Electrical equipment 400V/50Hz - Switch cabinet cooling unit - Machine feet - Painting RAL 9002 (grey white), RAL 5010 (gentian blue) - Rinsing gun with hose and holder in the operating area - Approx. 5 pcs. grinding wheel flanges *** Machine prepared for grinding mist suction *** Grinding programs - Surface grinding - Plunge grinding - Profile grinding - Automatic program sequence with roughing, finishing, fine finishing and burnout - Multiple plunge-cut grinding for economical production - Surface grinding with continuous, infinitely programmable cross feed - Calibration of the grinding wheel (calibrate, backfeed, round corners) - Face grinding with back pull dressing - Dressing in grinding cycle with lift-off amount - Fully automatic compensation of dressing amounts - Tool management Dressing Technology Table dresser -straight- TAG: Dresser fixed on the machine table, roughing and finishing station with dressing tiles are arranged one behind the other, cylindrical dressing of grinding wheels for surface and plunge grinding, suitable for corundum and silicon carbide grinding wheels, cycle software with input menu Pre-profiler VPG-150: incl. diamond roughing wheel width 1.5 mm For economical pre-profiling (roughing out) of the grinding wheel, profiling unit firmly mounted on the table, suitable for corundum and silicon carbide grinding wheels, CNC dressing cycle for pre-profiling Table profile dresser TAD: Suitable for diamond wheel DFR, D = 120, tip radius r = 0.1 - 1mm, flank angle 28°,40°, 60°. Profile depth max. 20 mm, contour accuracy +/- 0.0025 mm, swivel angle +/- 70°, profiling in the program by means of graphical operator guidance in 3-D interpolation

Datasheet

Request / Contact