Band Saw - Automatic - Horizontal

Machinelist: Band Saw - Automatic - Horizontal

Band Saw - Automatic - Horizontal

- WeMa Antonius Pigge GmbH

- Barnstorfer Str. 3

- 49424 Goldenstedt

- Deutschland

-

+49 (0)444496700

+49 (0)4444967010 -

info@wema-pigge.de

www.wema-pigge.de

#2031-3676 · Band Saw - Automatic - Horizontal

MEP - Shark 280 SXI duty Halbautomat - - unbekannt -

Technical details

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66306 · Band Saw - Automatic - Horizontal

MEP - SHARK 230-1 NC HS 5.0 - - -neu- -

Technical details

SHARK 230-1 NC HS 5.0, electro-hydraulic two-column fully automatic band saw with semi-automatic function for 0° cuts of mild steel, stainless steel, Steel alloys, solid and profile material, with a maximum remaining piece length of 60 mm. - The cross section is max. 230x230 mm. - Numerically controlled band saw machines with the new, specially designed by MEP developed for Automatic Windows “CE” based Controls.SOME FEATURES: - User interface with 7” touch screen display and mechanical buttons for the operating functions of the sawing machine, guaranteed reliable Operation, simple and intuitive, and real-time control of all Cutting parameters. - Safety enclosure in accordance with the latest safety regulations Machinery Directive EN 13898/2007. - New fieldbus communication system with double microprocessor Serial connection. - Robust cast iron structure (G25) to compensate for vibrations Improve machine stability and protect the saw band

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66311 · Band Saw - Automatic - Horizontal

MEP - SHARK 350 CNC HS 4.0 - - -neu- -

Technical details

Automatic electromechanical band saw machine in two-column design for 0° Cuts on solid material and profiles made of steel, stainless steel and Steel alloys up to a maximum of 350x350 mm. The standard equipment includes: Powered chip conveyor, to be mounted on the right or left of the machine. Clamping pressure regulation of the vices. Feeder with vertical rollers for lateral material support. Sensors for initial material detection. Clamping pressure regulation. 300 programs can be saved. The machine is available with a 34 or 41 band - at no extra charge. Price on request.

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

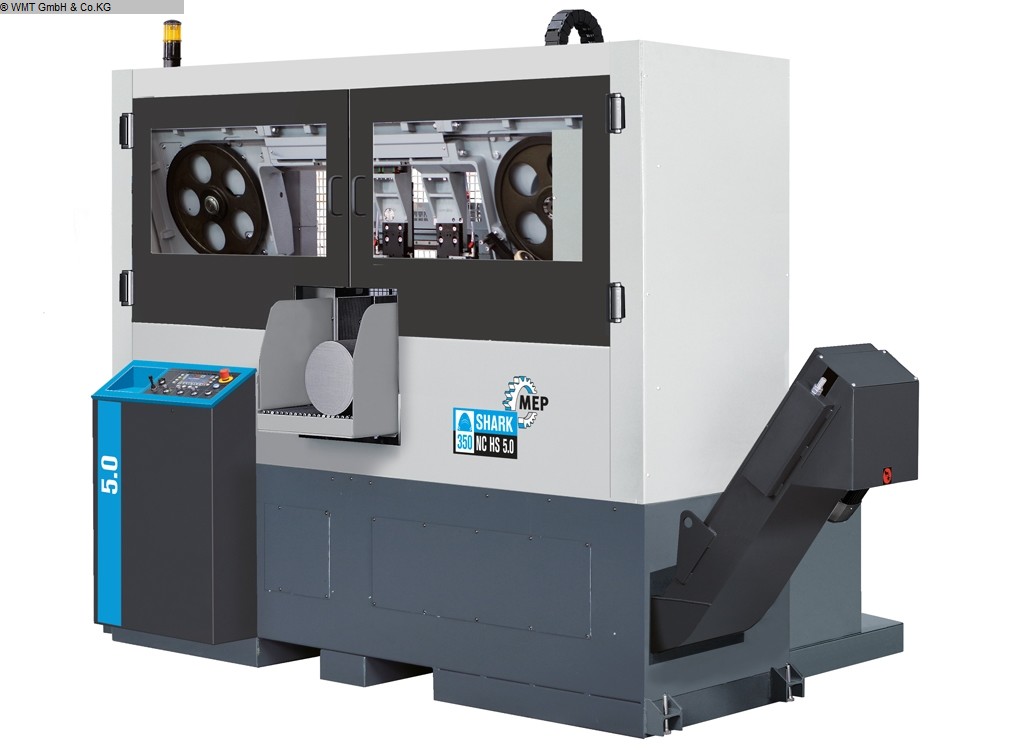

#1108-66307 · Band Saw - Automatic - Horizontal

MEP - SHARK 350 NC HS 5.0 - - -neu- -

Technical details

Shark 350 NC HS 5.0, automatic hydraulic band saw machine in two Column construction for 0° cuts on solid material and steel profiles, Stainless steel and steel alloys up to a maximum of 350x350 mm. The standard equipment includes: + Powered chip conveyor, can be installed on the right or left of the machine. + Clamping pressure regulation of the vices. + Feeder with vertical rollers for lateral material support. + Numerically controlled band saw machines, which are also operated semi- automatically can be done with the new MEP 50, especially from MEP for automatic Machine developed, Windows “CE” based control. + Cutting cycle “clean cut” The feeder pushes the workpiece at the back to avoid scoring on the cutting surface when the tape moves up again at the end of the cut. + Fieldbus communication system with double microprocessor and serial Connection. + The user interface with 7” touch screen display and mechanical Buttons are used to ensure the operating functions of the sawing machine reliable, simple and intuitive use, as well as a Real-time control of all cutting parameters

TOP Manufacturer:

BERG & SCHMID - KASTO - MEP - HUVEMA - AMADA - JAESPA - BEHRINGER - KALTENBACH - MEBA - MEP - VOLLAUTOMAT -